Cold flow characteristics of biodiesel blended petroleum distillates

Article by Dr. Sunil Kumar

Environmentally friendly fuels like biodiesel blended with petroleum distillates can have an impact on the cold flow property. Currently biodiesel is one of the choices which is renewable, biodegradable, and less toxic compared to fossil fuels. Biodiesel significantly reduces carbon dioxide, carbon monoxide, sulfur oxides, volatile organic compounds, particulate matter, and unburned hydrocarbons when compared to petroleum distillates like Marine Gas oils (MGO), very low sulfur fuel oil (VLSFO) and Heavy fuel oil (HFO).

Cold flow prediction of biodiesel blended petroleum distillates is very important when a ship is sailing through cold weather regions. The cold flow characteristics of a blended fuel can be different from the individual fuels used for blending. MGO, VLSFO and HFO basically originate from fossil fuels whereas biodiesel is from a renewable source. Both are essentially hydrocarbons but contains compounds with different structural characteristics and properties. So, the structural difference of the compounds responsible for the cold flow property shall be considered since it is a physical phenomenon. This will have an impact on the cold flow property of the fuel since the blend is from two different origins and can sometimes lead to unpredictable paraffin agglomeration.

Veritas Petroleum Services (VPS) has various test methods in place to evaluate the cold flow property of the biodiesel blended fuels. The Laboratory determined test results can help the ship operators to make the right decision how to handle the fuel at low temperatures.

Cold Flow Property of Biodiesel, MGO, VLSFO and HFO

Biodiesel, MGO, VLSFO, and HFO share a common characteristic: the presence of polymethylene groups influencing cold flow properties. The severity of low-temperature flow centers on the amount of heavier paraffins present, with longer polymethylene chains exacerbating the impact. Biodiesel, while advantageous in many respects, falls short in cold flow performance, prone to wax crystallization in colder climates, leading to potential filter blockage and potential engine damage. The composition of these fuels, particularly the presence of saturated and unsaturated paraffins, significantly affects their cold flow properties. Different feedstocks for biodiesel production yield varying performance in low temperatures; for instance, palm oil-based biodiesel fares worse than soybean-based biodiesel due to differing paraffin characteristics. Origin, whether plant or animal-based, profoundly influences cold flow properties, necessitating meticulous evaluation, especially in blends with MGO, VLSFO, and HFO. Proper assessment of low-temperature behavior is critical for blended fuels with diverse sources and characteristics.

VPS Laboratory Scale Evaluation

There are several test methods used to determine the cold flow characteristics in fuels like MGO, VLSFO, HFO, biodiesel, and their blends. VPS utilises four main methods: Cloud Point (CP), Pour Point (PP), Cold Filter Plugging Point (CFPP), Wax Appearance Temperature (WAT), and Wax Disappearance Temperature (WDT). CP indicates the onset of paraffin crystallization, serving as an estimate for operational limits. PP signifies near-complete paraffin crystallization and guides the lowest usable temperature. CFPP indicates filter clogging due to paraffin crystallization, impeding fuel flow.

Each test offers insight into how a fuel behaves in cold conditions. However, methods ISO3015 (visual method) and ASTM D5773 (optical light source) can only be used to measure cloud point when the “petroleum products are transparent in layers 40mm in thickness”. For this reason, VPS researched and developed an “Automatic Test Method for Wax Appearance Temperature of VLSFOs” and published a White Paper on this in 2019.

VPS Innovative (WAT/WDT) method for Non-Transparent Fuels

The ASTM D5773 method is used to determine the cloud point of clear petroleum products and biodiesels. VPS's innovation extends this to dark fuels like VLSFO, HFO, and biodiesel blends.

The VPS developed method WAT/WDT test offers a comprehensive view of wax appearance and crystallization temperatures in blended biodiesel with MGO, VLSFO, and HFO. This provides an extensive insight into low-temperature behavior, complementing conventional tests. There's a correlation between cloud point and WAT, both marking the onset of wax appearance.

Appendix 1 and 2 details some test results of various fuel types identifying the variance in the cold flow properties that are identified by tests in addition to the conventional ISO 8217 tests.

VPS Innovative Gas Chromatography (GC) method for the Biodiesel Impurities in the Fuel Blend

Impurities in biodiesel with FAME, arising from incomplete transesterification of feedstocks, can impact cold flow properties. Elevated total glycerol due to incomplete conversion and glycerol residue can cause issues like injector deposits and clogged systems. These impurities can affect cold weather performance when blended into fuels. Compounds like saturated monoglycerides (SMG) can precipitate above the blend's cloud point, potentially causing filter plugging. EN 14105 assesses free glycerol and residual glycerides in B100. VPS's innovative GC method determines mono-, di-, triglycerides, and free glycerol in biodiesel blends with MGO.

Conclusion

The diverse paraffin compositions in biodiesel blends pose challenges in establishing a general cold flow property relationship. These paraffins, from both biofuel and fossil fuel origins, add complexity to the crystallization process. The structural differences between biodiesel and diesel fuel compounds leads to an inconsistent flow behaviour of the blended fuel.

Given the unpredictable nature of low-temperature flow characteristics in blended biodiesel, comprehensive laboratory tests are crucial. Conducting CP, PP, CFPP, WAT/WDT, and GC analysis aids in understanding SMG in MGO blended biodiesel is recommended. Such thorough testing provides valuable insights into the cold flow properties of biodiesel blends.

For further information on how VPS can support you in your fuel management of marine biofuels, please contact: marketing@vpsveritas.com

Appendix 1

Cold Flow Property of Biodiesel Blend

Laboratory scale study has been carried out in order to evaluate the cold flow property of biodiesel blended fuels.

Following four fuels were selected for the Biodiesel blend study.

1. MGO

2. Low pour point VLSFO

3. High pour point VLSFO

4. HFO

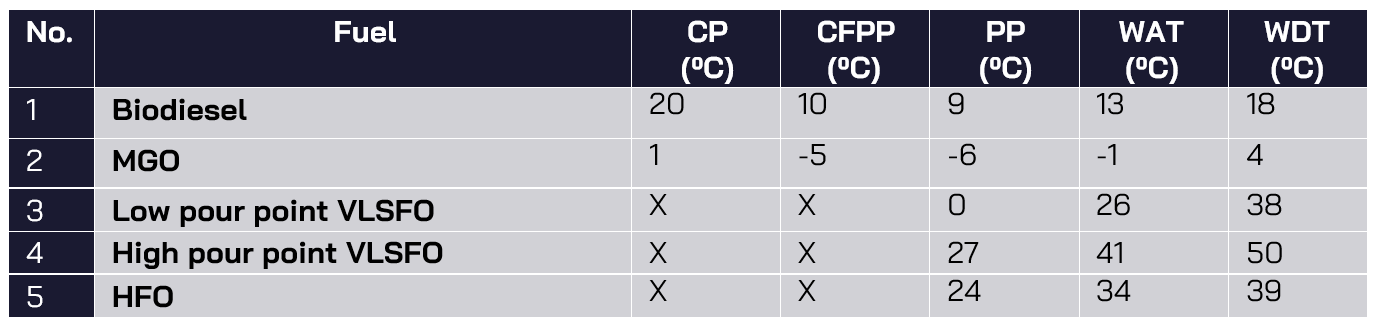

Prior to blending the fuels in various ratios, the cold flow property of the selected fuels (Biodiesel, MGO, Low and High pour point VLSFO’s and HFO) were determined and the results are given in Table 1.

Table 1 - Cold flow Properties

X: Not applicable

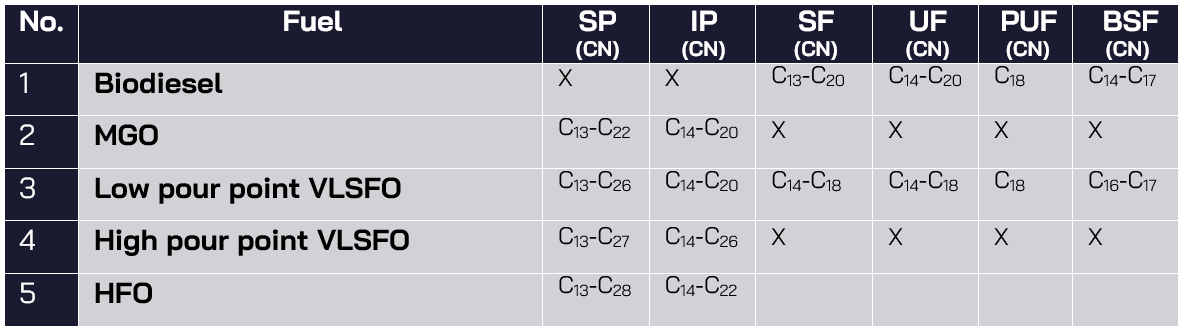

A general limited evaluation of the type of paraffins present in the MGO, Low and High pour point VLSFO’s, HFO and the FAME in the biodiesel which are responsible for the cold flow property was carried out by GCMS analysis on the 325⁰C vacuum distillate cut, and its carbon number represents the chain length of the polymethylene groups responsible for the cold flow property is given in Table 2.

Table 2 - Carbon Chain length of the Polymethylene Segments Responsible for CFP

CN-Carbon Number; SP-Saturated Paraffins; IP-Iso Paraffins; SF-Saturated FAME; UF-Unsaturated FAME; PUF-Poly Unsaturated FAME; BSF-Branched Saturated FAME; X-Not Present

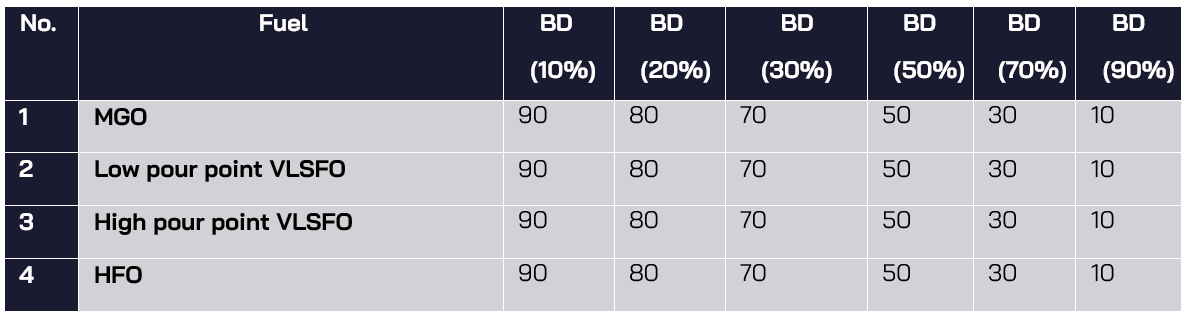

The four fuel types MGO, high and low pour point VLSFO’s, HFO was selected ande blended in different proportions with Biodiesel for cold flow property evaluation.

Table 3 - Blend proportion of MGO, VLSFO and HFO with Biodiesel

BD-Biodiesel

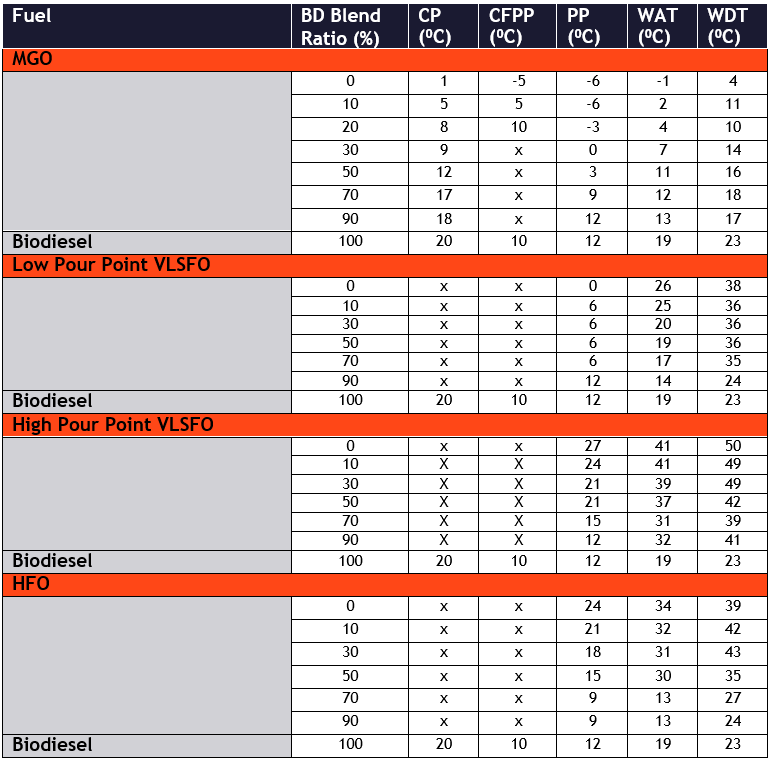

Table 4 - Cold Flow Property Results of Blended Fuels

Appendix 2

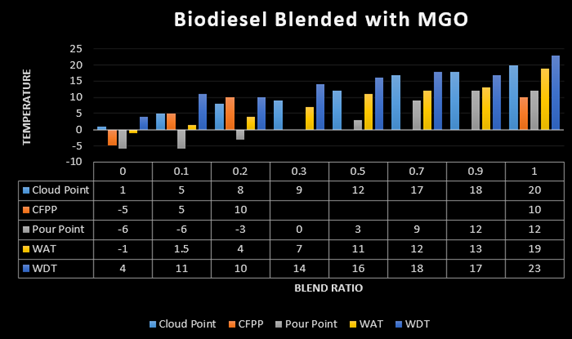

Biodiesel Blend with MGO

The low CP, CFPP, Pour point of the MGO indicates the presence of less concentrated long chain saturated paraffins. MGO blended with biodiesel in different proportions show an increase in the CP, CFPP, Pour point and WAT (Fig 1). The CFPP result of the 30% biodiesel blend resulted the filter clogging and this could be due to the crystallizable paraffin’s contributed from the biodiesel.

Fig 1 - Biodiesel Blend with MGO

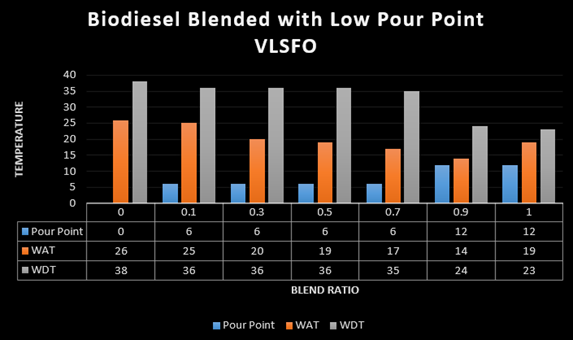

Biodiesel Blend with Low Pour Point VLSFO

The Low Pour Point VLSFO received has already contained fatty acid methyl ester compounds having saturated, unsaturated, and polyunsaturated polymethylene groups along with the saturated paraffins and iso-paraffins from the VLSFO. The VLSFO blended with biodiesel in different proportions shows a decrease in the WAT and a considerable drop has been observed at 10% VLSFO blend (Fig 2). It was observed that there is an increase in the pour point, but the increase was stabilized from 10% to 70% biodiesel blend and then a sharp increase at 90% blend. This shows the inconsistent wax crystallization behaviour of the blended fuel.

Fig 2 - Biodiesel Blend with Low Pour Point VLSFO

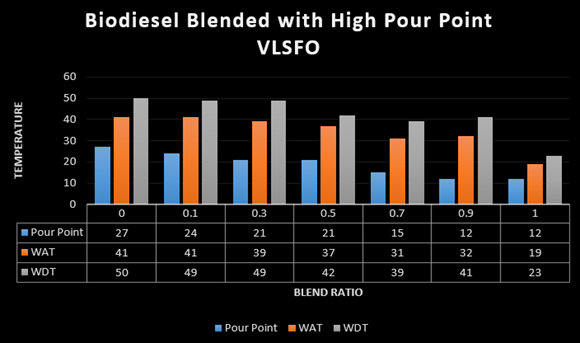

Biodiesel Blend with High Pour Point VLSFO

High Pour Point VLSFO blended with biodiesel in different proportions shows a decrease in the pour point and WAT, but a considerable drop hasn’t been observed from 10% to 70% blend (Fig 3).

Fig 3 - Biodiesel Blend with High Pour Point VLSFO

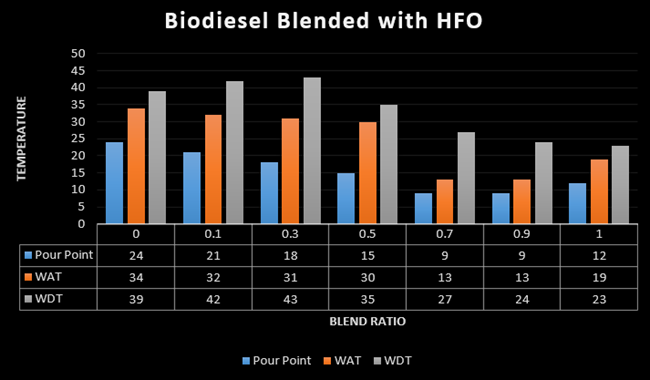

Biodiesel Blended with HFO

HFO blended with biodiesel in different proportions show decrease in the pour point and WAT, but a considerable drop has been observed above the 70% blend (Fig 4).

Fig 4 Biodiesel Blend with HFO

Search

Search

Customer

Customer