Maximising Lubricant Value

By Joe Star – VPS Strategic Account Manager.

Lubrication onboard

With thousands of litres of highly refined, and specifically formulated hydrocarbons flowing around a vessel at any one time, lubricating oils are the lifeblood of maritime operations, supporting a wide variety of applications.

Reducing friction, avoiding metal to metal contact, providing cooling and keeping components free of deposits and contamination, lubricating oils are required to perform a wide range of duties. To ensure that this is the case, all approved lubricants are rigorously tested and must pass performance thresholds outlined by the Original Equipment Manufacturer’s (OEM’s), culminating in viscosity, Base Number and other parameters that must be achieved by the “fresh” product prior to use.

As the lubricating oils circulate throughout the systems and engines onboard, these values can and will change, based upon the harsh temperature changes, mechanical wear and external contamination through the environment, or other fluids, entering the system. The typical oil analysis testing regimes per equipment are setup to monitor and steward this amongst equipment classes, with samples routinely taken on a quarterly, six-monthly or annual basis depending upon the demands of the equipment and stress the application places on the lubricant.

As engines and equipment continue to push for greater efficiency, ensuring the lubricant can keep up with these demands, maintaining expected drain or refill intervals is critical to operating a vessel efficiently. This places a greater importance on purification and filtration systems onboard.

The following whitepaper shares insights from VPS’ extensive database of lubricant oil results, providing actionable best practices to extract maximum value and longevity from circulating systems, monetising the purifier systems onboard.

Maximising lubricant value and lifespan

When reviewing overall vessel or fleet-wide performance across used oil analysis results, the key focus should be on understanding and identifying any repeat offenders which are present. This highlights examples where the root cause is not rectified and ongoing lubricant refreshment will only temporarily bring parameters back into compliance, which will then be quickly challenged operationally.

Assessing circulating systems, such as four-stroke engines, or circulating system oil within two-stroke slow-speed engines, operators should look to optimise the majority of any caution or alert results which are failures relating to Viscosity or Base Number.

This will highlight when the lifespan of the lubricant has been maximised based upon key base oil and additive properties within the lubricant.

Viscosity (mm²/s), is largely derived from the base oil within the lubricating oil and can be influenced by additive packages.

Operationally, Viscosity is one of the first parameters that provides an indication there are issues with lubrication within the system. These are either through increases due to oxidation, combustion and soot formation; or decreases via distillate fuel dilution or water ingress. Both detrimentally impact the lifespan of the lubricant and potential reliability of the asset, with longer term water ingress accelerating additive depletion. This can lead to the formation of emulsion within the lubricant, counter-intuitively increasing the viscosity over time.

As the lubricant is in use, its viscosity value will change over time and the property of the base oil within the lubricant remains; unless severe oxidation is identified. Lubricant viscosity and performance can be impacted by contamination. Yet appropriate dilution or removal of these contaminants can prolong the lifespan of the lubricant and this is where onboard lube oil purifiers assist. The value of ensuring the maximum value is attained from any onboard lubricant is only increased when the product in use is deemed as a “synthetic” product, due to the increased unit cost of the lubricants in question, and the extended drain intervals these products can achieve, provided the oil is maintained, tested and kept within degradation limits.

VPS’ database shows only 46% of caution or failure rates were due to Viscosity. Highlighting that over 50% of the samples which required action were subject to external contamination, such as Water or Iron (Fe).

Lubricant purification

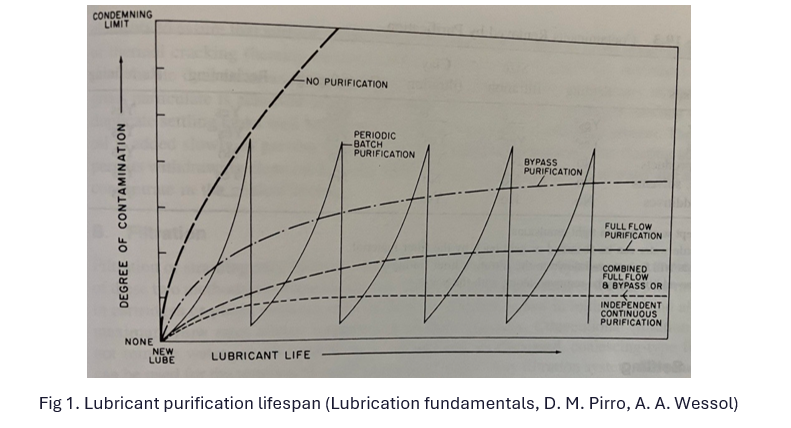

Onboard lubricant purification and filtration are critical tools in maximising the lifespan of lubricant onboard, as highlighted in the below graphical representation.

As is the case with centrifugal fuel purifiers and systems, removing critical contaminants such as, water and insoluble oxidised molecules, is the key and core objective of lubricant oil purification systems.

The majority of onboard lubricant oil purification systems operate via a centrifugal separator with a continuous water outlet, controlled by a gravity disc, in addition to a filtration system. The gravity disc of choice should be setup to match the oil density, viscosity grade, separation temperature and flow rate through the purifier. More recent separator models can adjust the interface without the need of specific gravity disc selection.

Operationally, the temperature of the lubricant oil that is passed through the purifier is the key variable that should be controlled, matching the relevant equipment manufacturer guidelines. The higher the temperature, the better the separation efficiency of the system, resulting in more effective removal of large particles (> 6 µm), and water from the lubrication system.

In typical systems, an increase in separation temperature from 90˚C to 95˚Cresults in a 22% separator efficiency gain. The impact of this can be identified through pre and post lubricant purifier analysis, notably through Water Content (H2O (%m/m)), PQ Index and ISO 4406 cleanliness code.

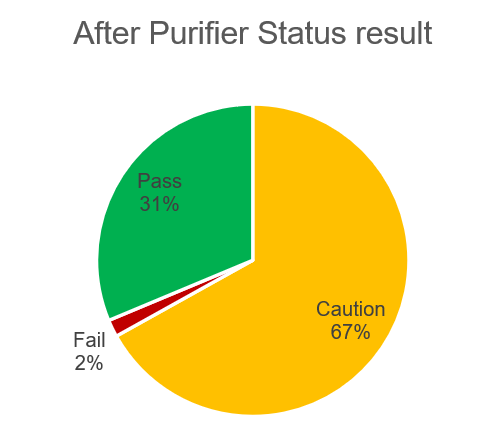

Reviewing VPS’ extensive database of lubricant testing data, the reported status of lubricant oil after purifier systems shows that over 2/3rds of all lubricant oils are at a caution or Alert/Fail status after purification.

The most common reasons for Caution or Alert results are due to:

• Elevated Water content

• PQ Index

• Elevated Viscosity

This data shows that whilst vessels have purification systems onboard, steps and actions based upon oil analysis results are required to ensure effective purification is undertaken, resulting in the prolonged lifespan of the lubricant. Notably, for lubricating oil where the pre-purifier water content is analysed at levels above 0.20 %m/m, a measurable decrease should be observed.

Interpreting and acting on analysis results

Aside from severe cases of contamination occurring within the lubricant oil, the key properties that should be assessed to understand purifier efficiency are:

• Water content (%m/m)

• PQ Index

• ISO 4406 PC code

Whilst some change in viscosity and Base Number may be witnessed, the removal of Water and free particles from the oil via the purifier is the most effective method to confirm acceptable purifier operation.

VPS recommends ISO 4406 Particle Counting (pre and post purifier) to be conducted to quantify the removal of different sized particles within the purifier and filtration system.

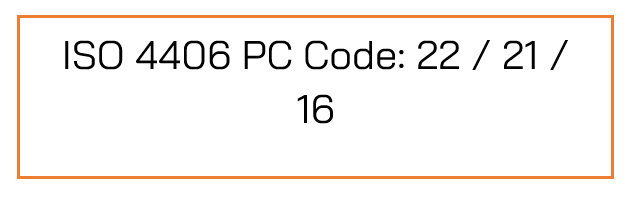

ISO 4406 Code:

The ISO 4406 Particle Count Code represents the logarithmic distribution and quantification of particles at different micron ranges, with differing equipment and oil cleanliness requirements based upon the application.

In the above example:

- 22 represents total particles above or equal to 4 microns in size

o 20,000 to 40,000 particles per mL - 21 represents particles above or equal to 6 microns in size

o 10,000 to 20,000 particles per mL - 16 represents large particle above or equal to 14 microns in size

o 320 to 620 particles per mL

Target ISO 4406 codes are set based upon application, with typical marine engines targeting between 20/18/15 to 22/20/17 cleanliness levels. These levels can and should be achieved through effective lubrication management and purification.

Due to the logarithmic nature of the ISO PC code, even a 1-2 quantification reduction can provide significant cleanliness benefits, as the most dangerous particles to engine and lubricant reliability are those greater than 6 microns in size. A 1-2 step reduction in Code 2 or 3 represents a halving, or quartering, of the total number of particles present that can cause further damage to engine components. When assessed against elemental analysis results, this can also provide an indication of the source of wear, which should be investigated and rectified.

Operationalising and monetising lubricant purifiers

Lubricant purifiers are a critical component in overall lubricant systems.

Therefore, provided the purifiers and filtration systems are operated effectively,

preventative maintenance strategies to extend component lifespan, reduce total lubricant consumption and minimise vessel operational expenditure, will be successful.

Key recommendations to optimise purifier performance:

• Lubricant oil samples to be taken pre and post purification systems to assess separator efficiency, particle and water removal.

• Separation temperature to be maximised where practically possible through the use of lubricant oil heaters, maintaining a temperature below 100˚C.

• ISO 4406 Particle Count to be conducted, alongside elemental analysis for wear identification and reliability risk reduction.

• Recurring contamination issues to be dealt with at source (i.e. fuel dilution based upon Vanadium detection for residual fuels).

• Trending analysis and data aggregation to be captured and stewarded across vessels and fleets.

For further support and advice on improving vessel operations via lubrication performance and efficiency contact joe.star@vpsveritas.com

Search

Search

Customer

Customer