Quantity shortage prevention for marine fuels

VPS Whitepaper by Captain Rahul Choudhuri & Renze Vonk

Summary

The transition of marine fuels to meet IMO 2020 Sulphur regulations has seen a greater supply of Very Low Sulphur Fuel Oil (VLSFO) and Distillate Fuel (MDO/MGO) to the shipping industry. This has raised the stakes on the cost associated with the transaction of these marine fuels for the foreseeable future.

This White Paper reports upon a VPS investigation into the quantity shortage risks and associated potential cost savings with these marine fuels, by evaluating the VPS Bunker Quantity Survey data. A statistically sound data set was considered for this survey, covering more than 10,000 bunkerings, carried out in 2019.

The final analysis of the VPS BQS data highlights the average financial losses relating to fuel delivery, per vessel per year, can be as much as US $96,200, even with low fuel costs at the time of writing. However, the cost of a VPS Surveyor to avoid such losses would only be an average US $15,000 per vessel per year, (depending upon duration and location of the bunkering).

This problem will be amplified when in addition there is a quantity shortage claim, undeclared Remaining Onboard Quantity (ROB), or a sampling dispute.

Investigation

The Bunker Quantity shortage risk potential for any bunker fuel delivery can occur for various reasons which may be categorized as follows:

1. The Ordered quantity & the Bunker Delivery Receipt quantity was different.

2. The Bunker Tanker delivered quantity & Bunker Delivery Receipt quantity was different.

3. The Bunker Tanker delivered quantity & the Vessel’s received quantity was different.

4. The Bunker Tanker delivered quantity fuel density was different from the Vessel’s received fuel density.

5. The ROB quantity on the vessel as measured by VPS Bunker Surveyor was different from that declared by the vessel’s staff.

Quantity Shortage

The VPS data for the average quantity shortage was evaluated using the Items 1 & 2 under VPS Bunker Surveyor strict quality control of the bunkering. The intention was to see the differential of these criteria as it is assumed that they should be the same during a fuel delivery. Our findings show otherwise.

The evaluation shows that on average, a quantity shortage of ‐6.6 M/tons or ‐0.5% of stem size occurred for every bunker delivery of Heavy Fuel Oil (HFO) & VLSFO. For the supply of MDO/MGO fuel, an average quantity shortage of ‐3.7 M/tons or ‐1.7% of stem size occurred.

In financial terms, this then equates to an average loss per loading of US$2,200 for VLSFO (US$330 per M/ton at time of writing) and US$1,400 for MGO (US$380 per M/ton at time of writing). So, for each bunkering, assuming a loading of VLSFO and MGO, the shortage potential would be US$3,600 and this translates to a loss of US$36,000 per annum (basis of 10 bunkering per ship per annum).

It is important to note that at a consolidated level, 7% of all bunkering showed an average quantity shortage of more than ‐20.0 M/tons for the same criteria. In such a case, this would equate to at least US$6,600 per bunkering.

Quantity Dispute

The quantity dispute claim under Item 3 refers to differences between the Bunker Tanker’s delivered quantity & the Vessel’s received quantity.

Our survey data shows that 4.6% of surveys resulted in a Note of Protest being issued for shortage claims. These shortage claims were on average ‐20.2 M/tons, equating to US$6,700 per claim.

With a fleet of 50 vessels, this would translate to 23 such claims to be expected per year totaling US$134,000 which is more reason to assure proper claims handling.

One of the added values of using a VPS Bunker Surveyor is that the detailed work performed in conducting the survey, preparation of the documentation and follow‐up investigation (as specified in the VPS BQS Code of Practice) ensures a 70% claims recovery. This level of detail enables the VPS Bunker Surveyor to indicate who is right or wrong, instead to leaving this to the buyer. This translates to a saving of US$2,200 per year per vessel.

ROB

Dispute The quantity shortage potential under Item 5 refers to the ROB quantity ascertained on the vessel by the VPS Bunker Surveyor as opposed to the ROB declared by the vessel’s staff.

It is not uncommon to find excess ROB quantity on the vessel. This means that the bunker quantity received by the vessel can be reduced by the excess bunkers found by the VPS Bunker Surveyor.

Following the onset of Covid‐19, VPS Bunker Surveyors have already uncovered 500 M/tons in excess onboard vessels for a single customer. This translates to a cost saving of US$165,000 over this short time period.

On average, where ROB surveys are conducted, excess bunkers of 15 M/tons per vessel has been found. This translates to US$5,000 per bunkering or US$50,000 cost savings per vessel per year.

Sampling Dispute

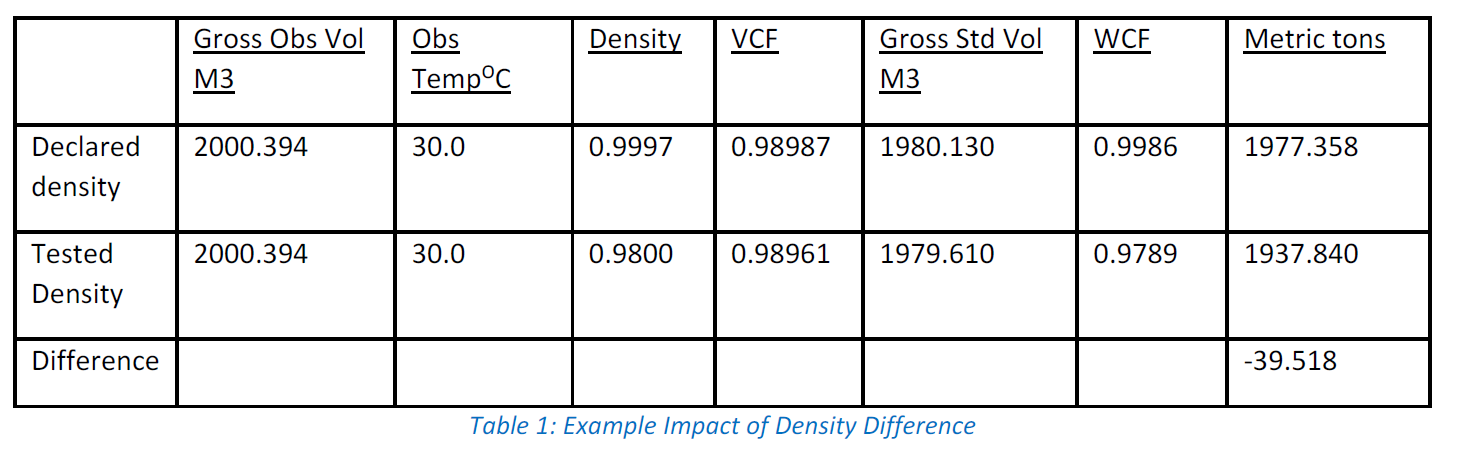

The bunker fuel product density & temperature determines the volume & subsequent tonnage of the bunker delivery.

VPS survey data shows an average density difference of ‐1.3 Kg/m3 per bunkering for VLSFO resulting in a shortage of about ‐1.9 M/tons per bunkering & which equates to a loss of US$600 per bunkering or US$6,000 per year; and an even higher 2.6 Kg/m3 difference for MGO which would be a shortage of 0.6MT and a corresponding loss of $200 or $2,000 per year. In total this translates to a potential cost saving of US$8,000 per year.

The accuracy of the density is dependent on the employment of the proper method & location of the sample collection. This excludes MFM deliveries.

Sampling disputes arises when the bunker fuel sampling is not undertaken in accordance with surveying standards resulting in a nonrepresentative sample. This is unfortunately still common in most bunker ports of the world where bunker tankers still do not take a representative sample due to lack of interest, improper equipment, or not following standards.

VPS sampling data shows that, without the presence of the VPS Bunker Surveyor, at least 20% of bunkering samples do not follow proper documentation. This will, in addition, reduce the chance of claims success for a fuel quality dispute where e.g. a single engine damage case can cost up to US$500,000.

The presence of the VPS Bunker Surveyor, throughout the entire fuel delivery, can therefore ensure that the sampling process is closely monitored, and internationally accepted survey & sampling standards are following in line with SS 600:2014 Code of practice for bunkering, SS 648:2019 Code of practice for bunker mass flow metering, ISO 13739:Petroleum ProductsProcedures for the transfer of bunker to vessels(Second Edition 2020‐02) & the VPS Bunker Quantity Survey Code of Practice 2019.

This will correct any incorrect bunkering practice & ensure that a truly representative sample at custody transfer is taken & documented to give the highest likelihood of successful claims handling.

Conclusion

1. An average loss of ‐6.6 Mons for MFO/VLSFO and ‐3.7 M/tons for MDO/MGO can be expected for a bunker delivery. This translates to a loss of US$3,600 per bunkering or US$36,000 per year per vessel. On 7% of cases, this loss can be higher at ‐20.0 M/tons which translates to a loss of US$6,600 per bunkering. The actual quantity loss can vary from port to port & further details are available in the VPS database of more than 70,000 surveys.

2. There is a 4.6% chance of a bunker quantity shortage of an average ‐20.2 M/tons during a bunker delivery where a Note of Protest is issued for a claim. This translates to a cost saving of US$4,700 per resolved claim, or US $2,200 per year per vessel.

3. ROB Quantity on vessels requires consistent monitoring to avoid excess bunker expense. Any undeclared bunkers constitute cost savings. The average excess ROB found onboard was 15 M/tons. This translates to US$5,000 per bunkering or US$50,000 per year cost saving per vessel.

4. Improper sampling can compromise a quantity dispute related to density. This translates to a loss of US$800 per bunkering or US$8,000 per year per vessel.

5. Overall, this investigation shows that bunkering activity needs to be methodically controlled with the constant presence of a knowledgeable & professional VPS Bunker Surveyor to avoid a quantity shortage situation. Failure to do this will result in a total bunker quantity loss in the order of US$96,200 per vessel per year. VPS is able to generate these savings through our high‐quality surveying service, underpinned by a detailed BQS Code of Practice and a rigorous training and refresher programme for all Surveyors. The engagement of a VPS Bunker Surveyor at approximately 15% of this cost will not only save money, but significantly reduce management stress, time & reputation.

Search

Search

Customer

Customer