WAT'S going on with VLSFO's?

Article published in Bunkerspot

Steve Bee advises that the industry must be prepared to recognise and deal with the many different characteristics of the VLSFOs now coming onto the market

There is a very British saying which is: ‘It’s a completely different ball of wax.’ It is used to emphasise when, or where, two things are completely dissimilar to one another. Compliance with IMO 2020 has driven the introduction of a number of new marine fuel types which are being brought to market. These fuels have already shown certain characteristics which are markedly different from the traditional residual and distillate fuel-grades historically encountered in the maritime industry and they are indeed almost literally, ‘a completely different ball of wax’.

Even within this group of new fuels, all being broadly termed very low sulphur fuel oils (VLSFOs), there are many where their only common characteristic is the fact they have a sulphur content of 0.50% or lower. Many of these fuels are blended products (ULS distillates + LS residues), utilising hydro-treated vacuum gas oils and hydrocracker fractionator bottoms as part of their make-up. In addition, various other cutter stocks, diluents and additives may also be present within these fuels. This level of variation in components leads to a wide range of chemistries and considerations regarding the management of such fuels.

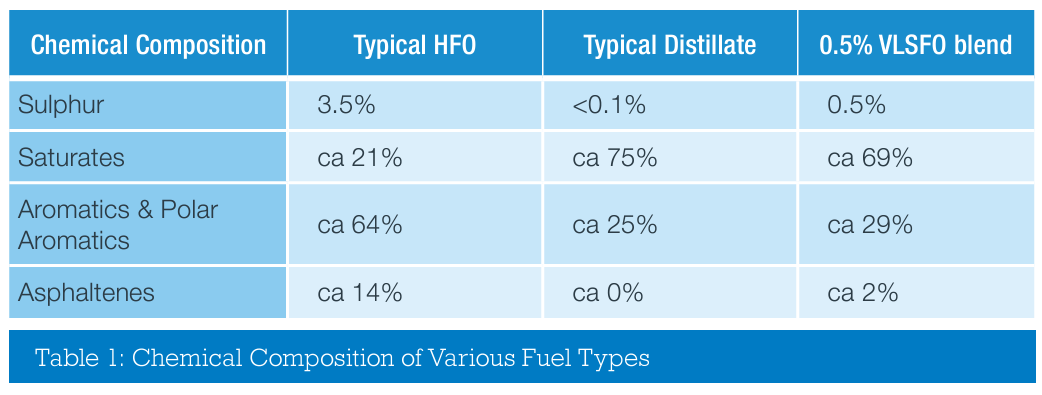

One key consideration regarding the fuel management of VLSFOs is their paraffinic content. In the world of chemistry, paraffins, also known as ‘saturates’, exhibit excellent ignition and burn properties, making them ideal fuels. However, one potential issue with paraffins is, when held at certain temperatures, they can precipitate a wax. Many of the new VLSFO fuels have a much higher saturate, or paraffinic content than residual heavy fuel oils (HFOs) which are currently the most commonly used marine fuels. As shown in Table 1, VLSFOs can have three times the level of saturates than a typical HFO and half their aromatic content. This means there is a far greater potential for wax precipitation from VLSFOs than there is from HFO.

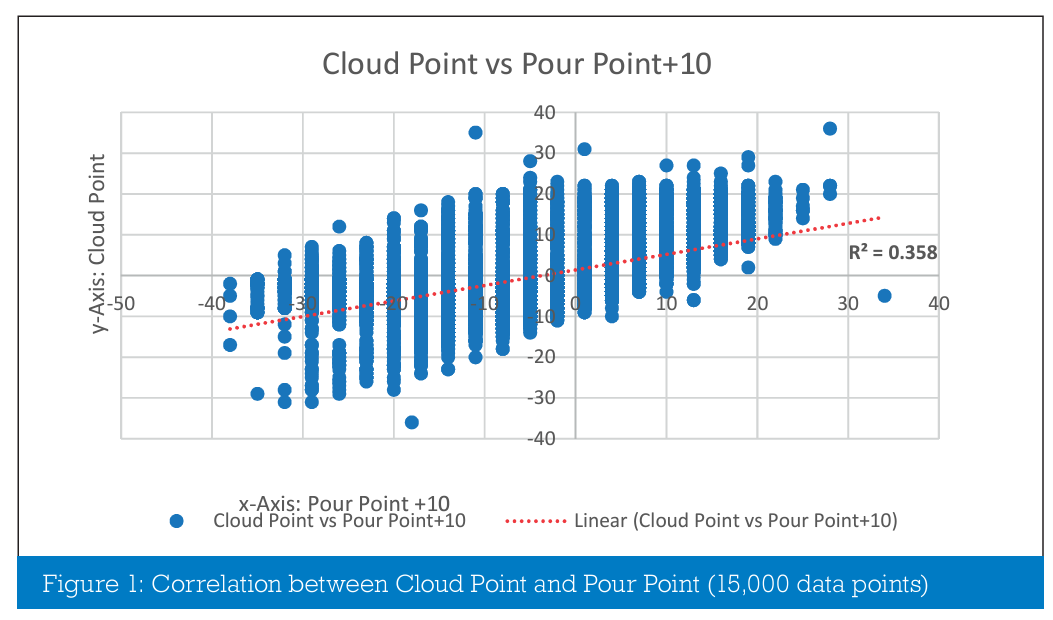

The temperature at which wax precipitation starts is dependent upon the chemical composition and this varies from fuel to fuel. Should the wax precipitate it can block a vessel’s pipework and filters and ultimately starve an engine of fuel and cause many onboard operational problems. Therefore, the determination of the temperature at which wax precipitation starts is an incredibly important measurement with respect to the cold-flow risks of VLSFOs. There are currently three common cold-flow measurement parameters with associated international test methods that cover the potential of a fuel to wax – i.e. Cloud Point (CP), Cold Filter Plugging Point (CFPP) and Pour Point (PP). Distillate fuels can utilise all three parameters as they are visually clear. However, HFOs and VLSFOs can only employ pour point due to their opacity. It should be noted that Cloud Point (CP) is a fundamental cold-flow property since it indicates the temperature at which wax starts to form. Therefore, fuel held above its CP will always flow. As CP cannot be measured in opaque fuels, the historic advice has been to store such fuels at PP+10°C, that is 10°C above the PP. However, the visual PP test method (ISO3016) is a subjective visual test, with poor repeatability and reproducibility. It is also known that there is poor correlation between PP and CP, as indicated in Figure 1.

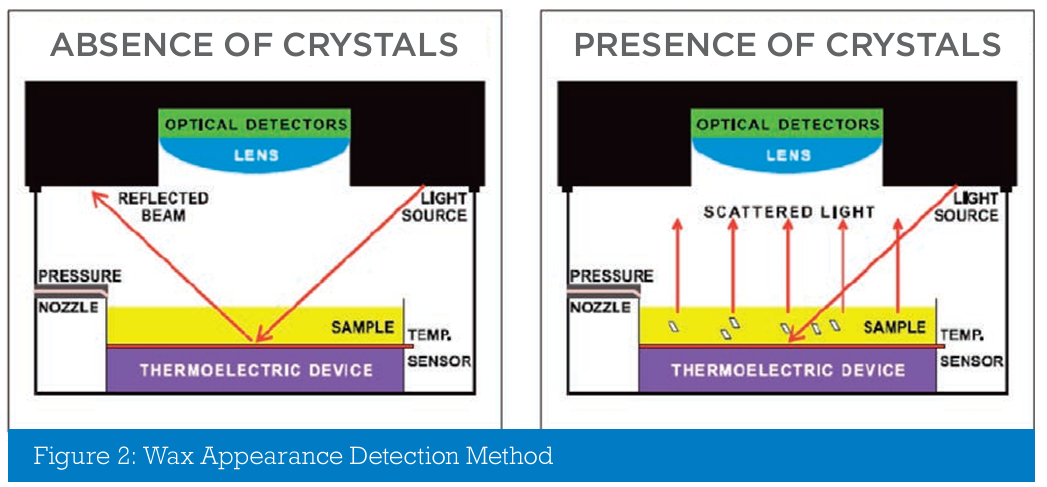

Furthermore, PP is affected by the presence of additives within a fuel, whilst CP being a fundamental fuel property is not. Due to the high paraffinic content of VLSFOs, wax may precipitate at temperatures far higher than the current PP +10°C guidance. A much more reliable method of monitoring the likelihood of fuel waxing is to measure the CP. In order to overcome the issue of not being able to measure the CP of opaque fuels and to provide valuable information with respect to the cold-flow of VLSFOs, VPS has developed an in-house method for the measurement of the Wax Appearance Temperature (WAT) of VLSFOs (WAT is the same as CP). In addition, VPS developed this equipment to measure the Wax Disappearance Temperature (WDT), which is the temperature at which the last wax solids are melted into liquid when the oil is warmed. As such it provides an indication of the temperature that the fuel must be heated to in order to fully dissolve any wax solids that have precipitated. This method is based upon ASTM D5773, utilising a light-scattering optical measurement within the near-infrared spectrum as shown in Figure 2.

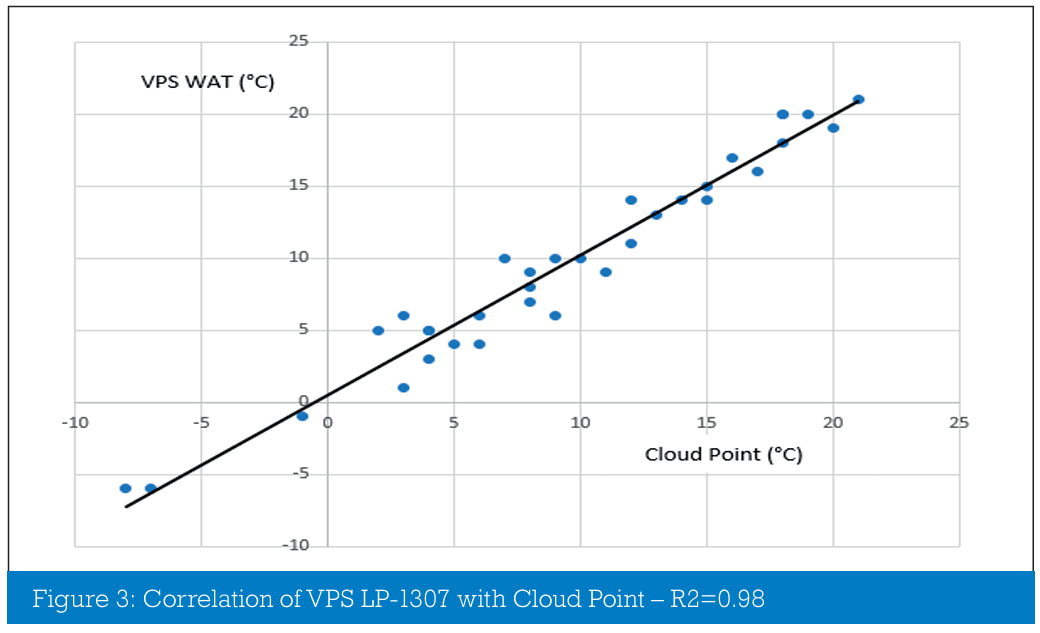

VPS has undertaken significant R&D work to modify the test equipment and method in order to optimise the test method (VPS-LP1307) for VLSFOs. In order to validate the VPS LP1307 method, several distillate blends were tested in both the non-visible light and then by the standard method in the visible light. Very good correlation of R2=0.98 was achieved as in Figure 3.

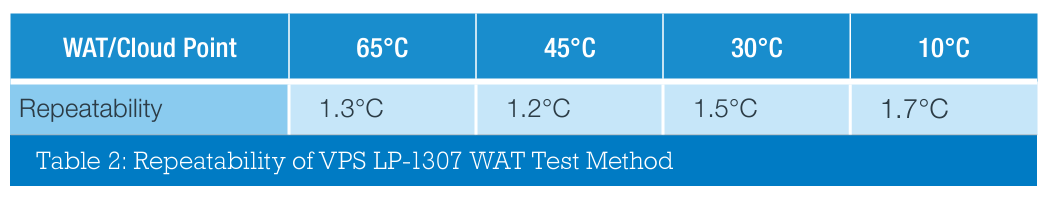

Extensive work on the method VPS LP1307 also proved the test has excellent repeatability, as in Table 2.

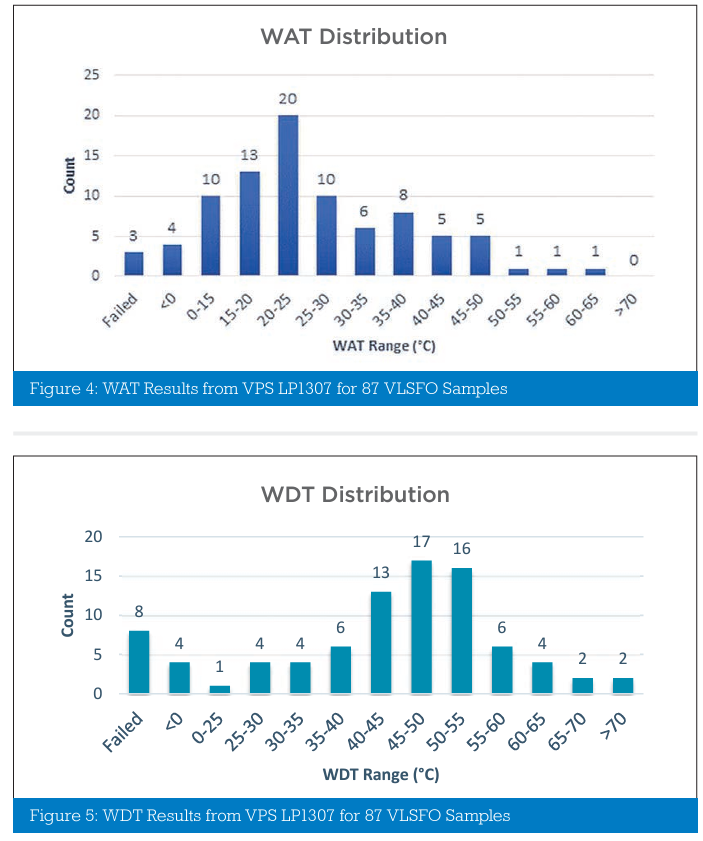

Over the past months, 87 currently available commercial VLSFO samples from fuel bunkered in Singapore, Rotterdam, Fujairah and Houston were tested using the new VPS method. These VLSFOs showed a very wide range of Wax Appearance Temperatures (0°C-65°C), with many at elevated temperatures, demonstrating VLSFOs must be maintained at much higher temperatures than traditional HFOs, and the operational importance of measuring WAT. The WDT for those same 87 VLSFOs, showed how much higher temperatures need to be to ensure the wax has fully melted, once it has been allowed to appear, (0°C - 70°C +). The temperature difference between WDT and WAT can be up to 20°C or more, in certain cases. Using this new VPS test method, key fuel management and operational information can be obtained for the new VLSFOs in relation to safe storage, transfer and overall handling of these new fuels with respect to their specific Wax Appearance Temperature. Fuels maintained above their wax appearance temperature will always flow, thus preventing cold-flow problems. However, should the fuel be allowed to fall below their WAT, then their specific WDT will indicate the temperature required to ensure the wax has fully dissolved.

So far, the VLSFOs coming to market are all exhibiting many different characteristics and test parameter variations, not only in comparison to traditional marine fuels, but even between the many different VLSFO products themselves. Now with the means to measure Wax Appearance Temperature for the first time in these fuels, we can see the wide range of temperatures at which wax can appear and how prior knowledge of this temperature can help avoid many cold-flow operational problems. VLSFOs are indeed ‘a completely different ball of wax’.

To obtain a copy of the VPS Technical Paper relating to this new test method please contact Steve Bee at steve.bee@vpsveritas.com

Search

Search

Customer

Customer