Steve Bee – VPS Group Marketing & Strategic Projects Director &

Emilian Buksak – VPS Decarbonisation Advisor

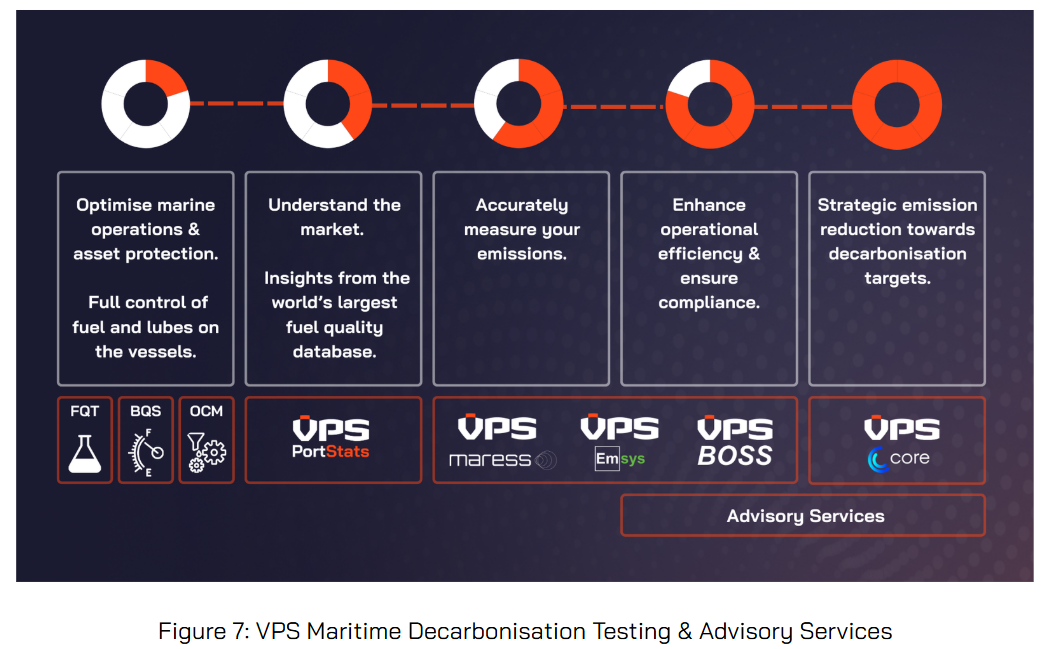

As far back as 1981, long before the word “sustainable” was ever applied to the protection of the planet, VPS marine fuel quality testing (FQT) service was clearly focused on achieving a sustainable global shipping fleet. Even before the existence of any international marine fuel quality standard, VPS was testing fuel to ensure the protection of, vessel operations and engines, crew health & safety and the environment.

At present, global shipping is navigating its way on a voyage to decarbonisation and sustainability, with increasingly complex regulatory and legislative requirements being placed upon vessel owners and operators. In support of such requirements, digitalisation and the demand for immediate accurate data, along with the use of low-to-zero carbon fuels, are now necessities within shipping, as it strives to achieve numerous levels of compliance.

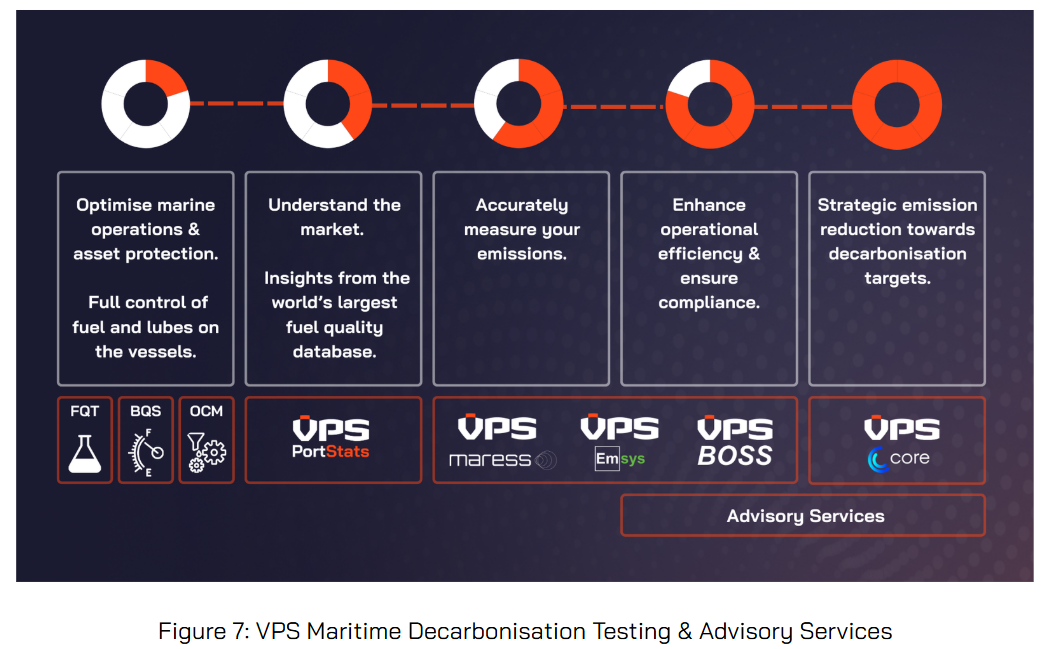

Today, VPS continues to provide market-leading testing and inspection services that support shipowners & operators to comply with and go beyond regulatory requirements, by extending the lifetime and usage of fuels and lube oils and indirectly that of the assets in which they’re employed. VPS testing and data solutions support vessel operators by providing comprehensive services that bridge the gap between complex regulations and practical, day-to-day operations.

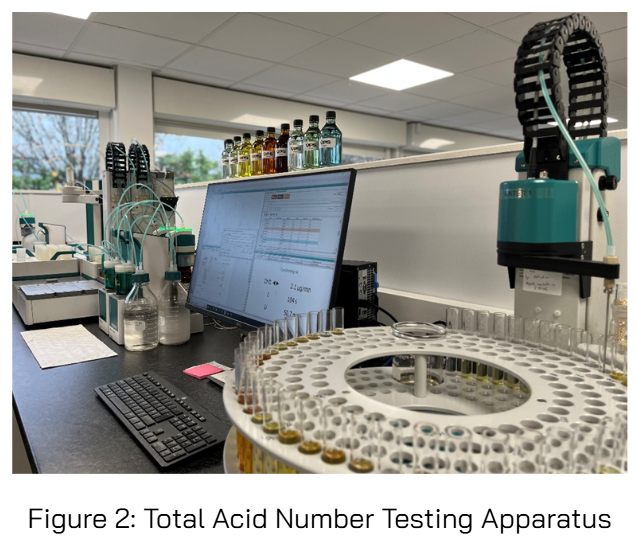

Through fuel quality testing, VPS verifies a vessel’s fuel, be it fossil, bio-based or methanol, that it’s meeting current stringent specifications. By identifying quality issues early, operators avoid engine damage, unplanned downtime, and expensive retrofits. Even as new low-carbon fuels enter the market, VPS’s in-depth testing ensures every batch is “fit for purpose,” giving vessel operators confidence as these alternative fuels are being assessed. Through the test data generated VPS helps its customers gain the most value from their procured fuels.

Rigorous lubricant testing complements this, helping fine-tune equipment to maintain operational efficiency and reduce downtime. Additionally, VPS deploys emissions measurement equipment to gather accurate data crucial for both compliance reporting and operational insights.

Then, beyond testing and its associated data services, VPS offers decarbonisation software and advisory services spanning strategic decarbonisation planning, to vessel fuel performance optimization, including speed and power generation management, technical and operational efficiency initiatives, and even basic crew training. By pinpointing improvement areas across a vessel’s operating cycle, VPS helps reduce fuel consumption, lower emissions, and ultimately support operators’ transition to cleaner and more cost-effective operations.

But first let us look at the current legislative requirements and its challenges.

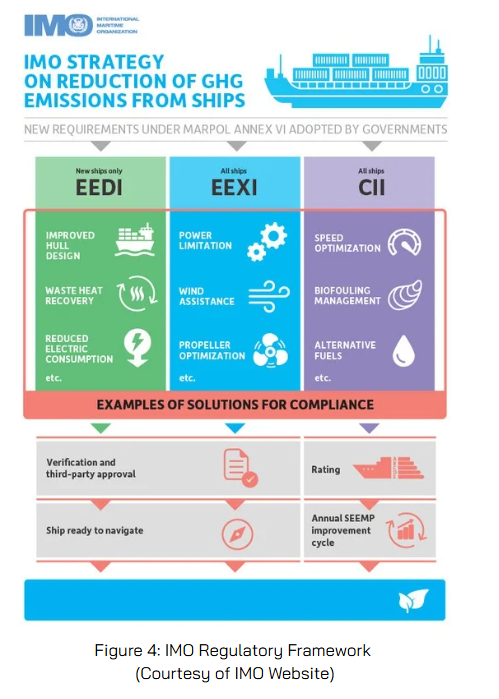

From the initial implementation of the International Maritime Organisation (IMO) MARPOL Annex VI, coming into force on 19th May 2005, shipping has witnessed numerous levels of legislation being introduced to which vessels must comply.

Decarbonisation targets, are driven in the main by the IMO and its initial strategy for a reduction in the carbon intensity of international shipping (to reduce CO2 emissions across international shipping, by at least 40% by 2030, pursuing efforts towards 70% by 2050, compared to 2008) and that total annual GHG emissions from international shipping should be reduced by at least 50% by 2050 compared to 2008.

In 2023, IMO introduced a revision to its decarbonisation strategy, stating the carbon intensity of ships needs to decline through further improvement of the energy efficiency of new ships. Also, the need to strengthen the energy efficiency design requirements for ships, leading to a reduction in the carbon intensity of ships, so supporting the reduction of CO2 emissions by at least 40% by 2030, compared to 2008. Also, the uptake of zero or near-zero GHG emission technologies, fuels and/or energy sources to increase and represent at least 5%, striving for 10%, of the energy used by international shipping by 2030 and GHG emissions from international shipping to reach net zero by or around 2050.

This strategy revision introduced Indicative Checkpoints, to monitor the progress of the reduction of the total annual GHG emissions from international shipping by at least 20%, striving for 30%, by 2030, compared to 2008 and the reduction of the total annual GHG emissions from international shipping by at least 70%, striving for 80%, by 2040, compared to 2008.

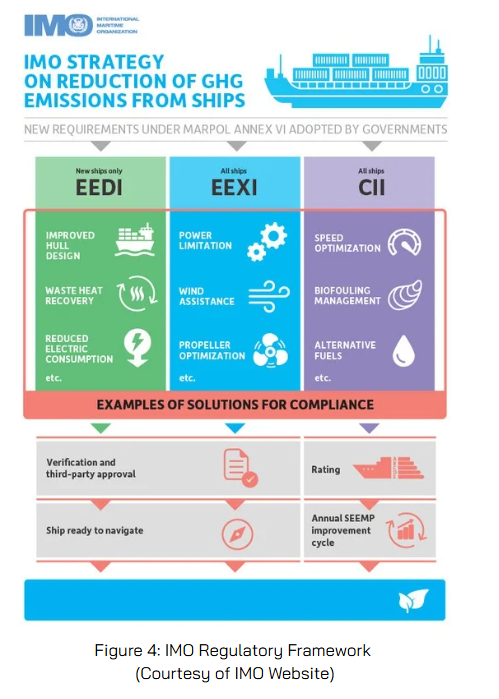

The IMO GHG strategy is supported by:

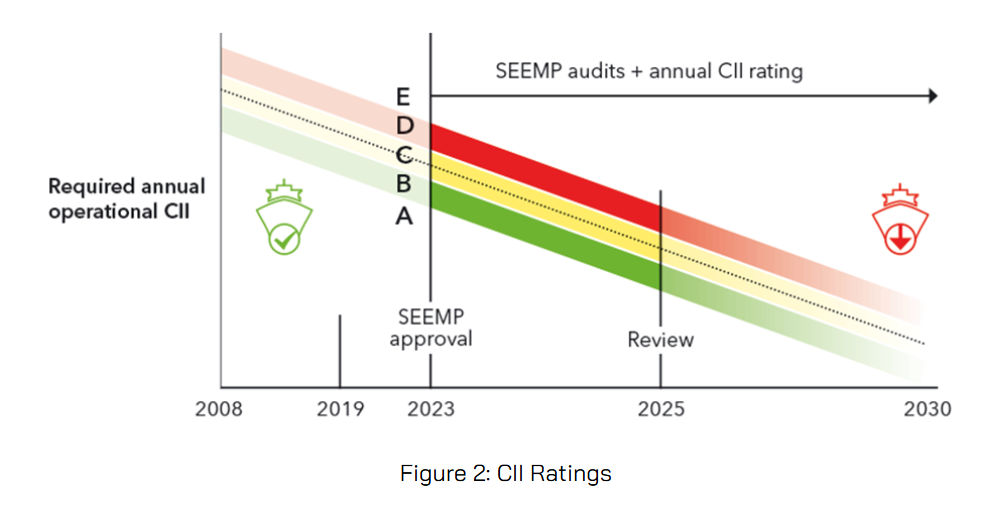

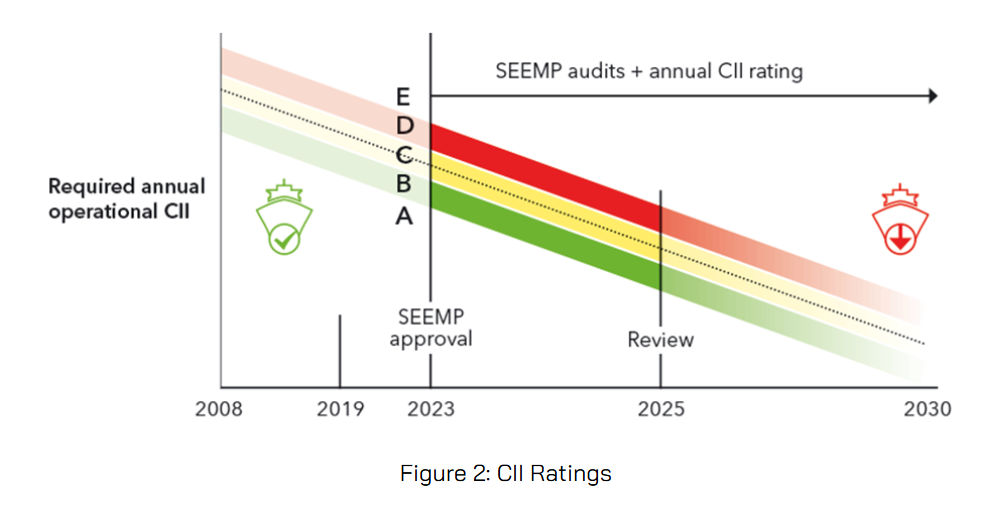

CII - Carbon Intensity Index, which determines the annual reduction factor needed to ensure continuous improvement of a ship's operational carbon intensity within a specific rating level. The ratings go from an inferior performance level – E, to the major superior level – A. Measuring the CO₂ emitted per cargo-carrying capacity per nautical mile, CII incorporates, speed optimization, biofouling management and alternative fuels usage.

Each year it becomes more difficult for a ship to improve its CII rating. But the best performing vessels are likely to trade at a premium.

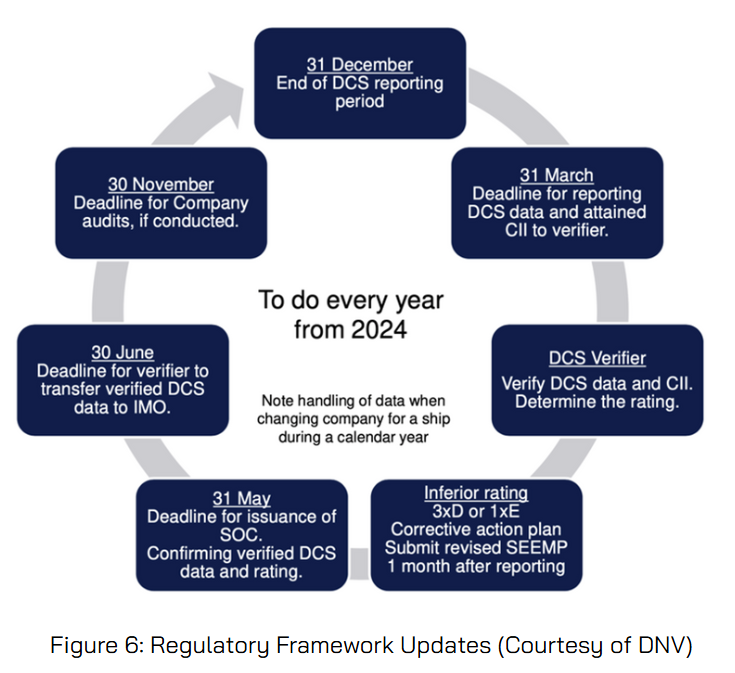

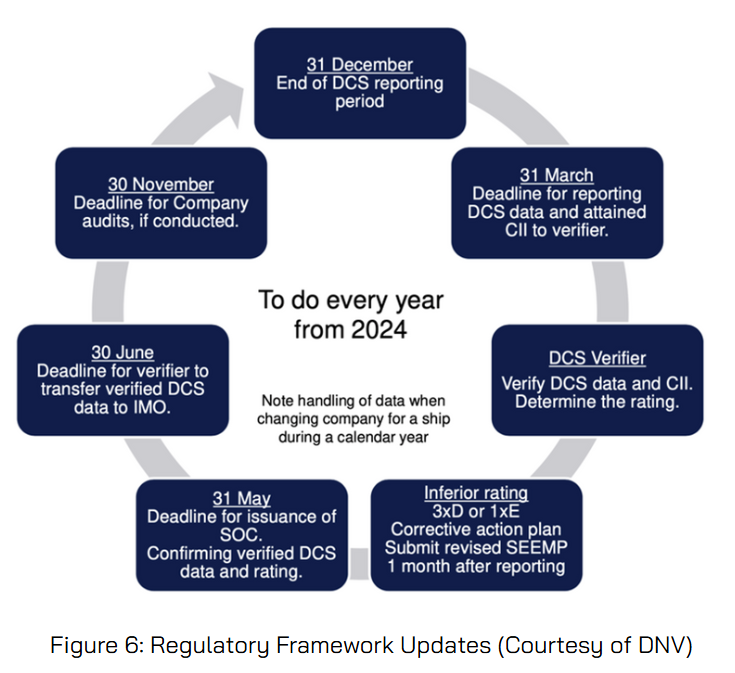

Since 2024, the CII must be calculated and reported to the Data Collection System Verifier along with the previous year’s aggregated DCS data. This must include any correction factors or voyage adjustments. The deadline for DCS and CII submission is no later than 31 March each year.

The attained annual operational CII and the environmental rating (A to E) is noted on the DCS Statement of Compliance (SoC), which is required to be kept on board for five years.

In case of a D rating for three consecutive years or one E rating, the Ships Energy Efficiency Management Plan (SEEMP) Part III must be updated with a corrective action plan and verified before the SoC can be issued. The corrective action plan should consist of an analysis of why the required CII was not achieved and include a revised implementation plan.

It is worth noting at this point that the use of low-carbon fuels such as LNG, Bio-LNG, Biofuels and Methanol, offer immediate emissions reductions, which will significantly assist vessels improve their CII ratings and comply with the tightening regulations.

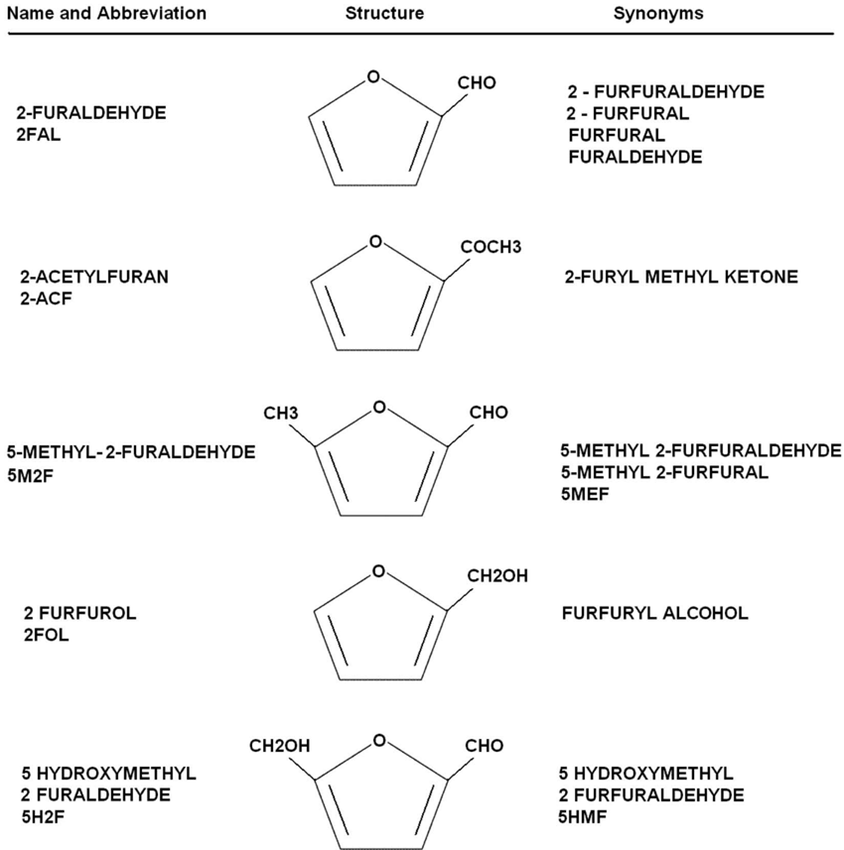

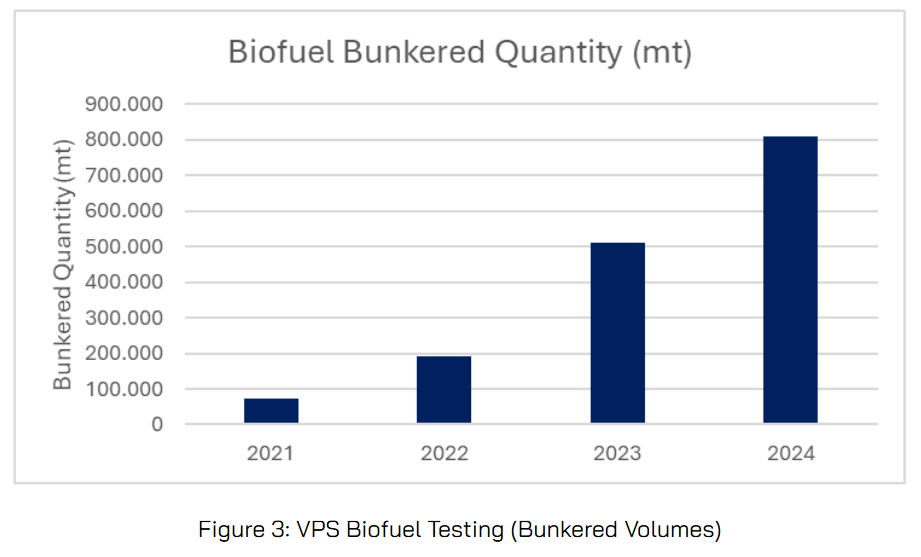

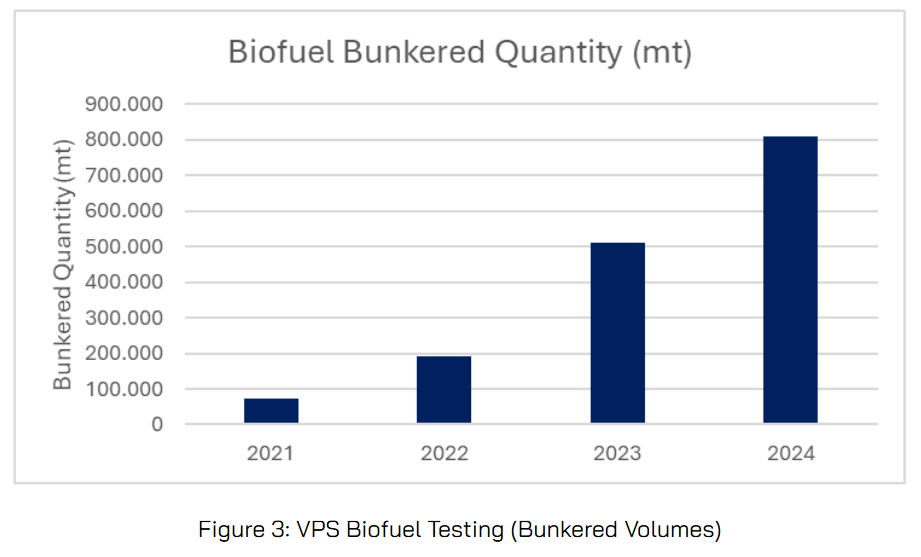

For over four years VPS have led the market in the understanding of marine biofuels and methanol. VPS laboratories have undertaken significant R&D work regarding innovative testing technologies and methods, to assist in improved fuel management and environmental compliance. Between 2021-2024 VPS tested samples equating to over 1.6million mt of delivered biofuels. This work has covered bio-components such as the most common FAME, plus HVO, Cashew Nut Shell Liquid (CNSL) and Tyre Pyrolysis Oil (TPO). Such experience and expertise are then passed on to VPS customers to enhance their understanding of such fuels and achieve the emissions reduction and efficiency improvements required.

EEDI - Energy Efficiency Design Ship Index, relates to new vessels, built post-2013. This sets a baseline for CO₂ emissions based on ship type and size. It is calculated as the amount of CO₂ emitted per ton of cargo transported per nautical mile, emphasizing fuel efficiency and environmental performance. Considerations are hull design, waste heat recovery and reductions in electricity consumption.

EEXI - Energy Efficiency Existing Ship Index introduced from 1st January 2023 for vessels over 400 GT. EEXI indicates a ship’s energy efficiency compared to a baseline. The attained EEXI is then compared to a required Energy Efficiency Existing Ship Index based on an applicable reduction factor expressed as a percentage relative to the Energy Efficiency Design Index (EEDI) baseline. EEXI takes into account such areas as power limitations, wind assistance and propeller optimization. Ships struggling with EEXI are likely to face difficulties with CII compliance.

VPS BOSS software application can assist in providing key deep-sea vessel operations data analytics towards CII. Monitoring engine load, fuel consumption, RPM and speed. In addition, BOSS offers proactive route optimisation taking advantage of favourable sea currents, with speed adjustments along the entire journey, considering weather, voyage costs and commercial factors like voyage priority and laycan window. This strategy enables the vessel to save 3-5% on fuel costs, reduce CO2 emissions, and improve the CII rating.

For offshore vessel efficiency improvements, the VPS Maress software offers a similar approach, in reducing fuel usage and emissions, supporting improvements to vessel CII performance. The past two summers have seen over four hundred offshore vessels join the VPS Maress Summer Campaign, a 3-month project to see how much CO2 emissions can be reduced, which has resulted in a reduction of over 17,000mt CO2. At present there are over 600 vessels using Maress to support their decarbonisation efforts.

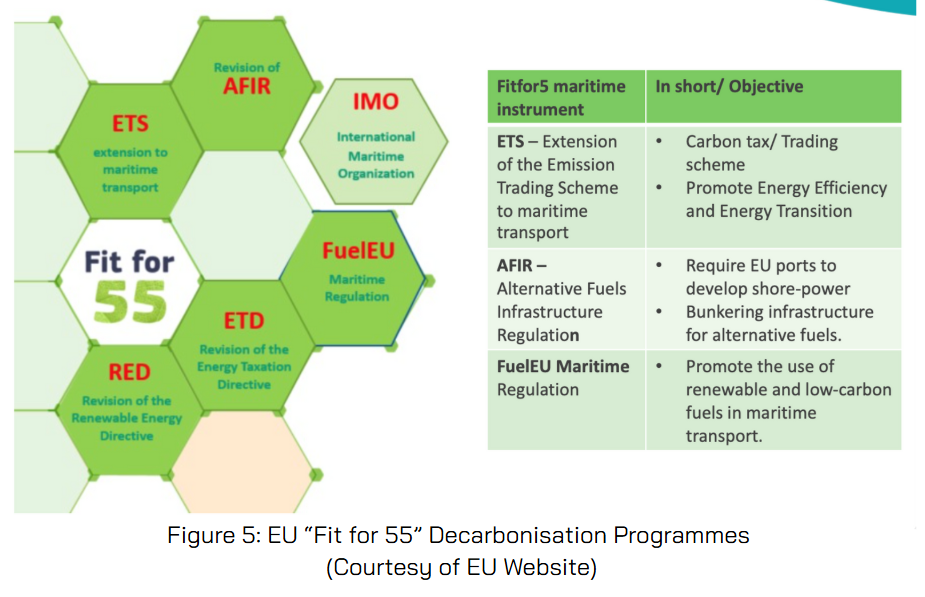

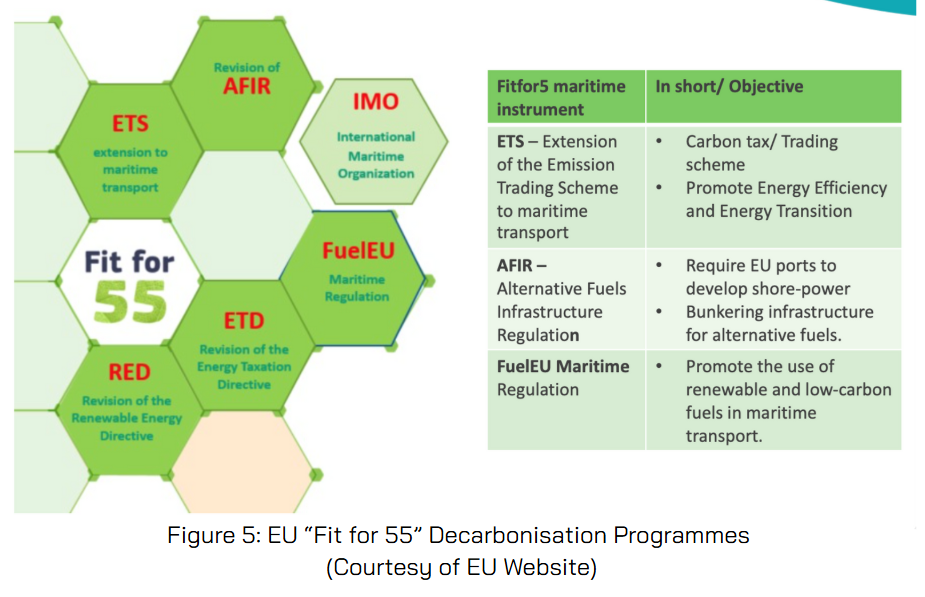

The EU’s GHG strategy is driven mainly through:

Fit for 55 – Which includes a number of decarbonisation components:

EU ETS - The EU Emissions Trading System which is a cap-and-trade mechanism designed to reduce greenhouse gas (GHG) emissions. Basically, EU ETS is a carbon tax/trading scheme. Under this system, companies are required to purchase permits, or allowances, (EU Allowances, EUAs), that grant them the right to emit a specified amount of GHGs. One EUA allows emission of 1mt of CO2-equivalent, which need to be surrendered to a vessel’s administering authority to cover emissions from voyages to and from, plus between European Ports and port stays.

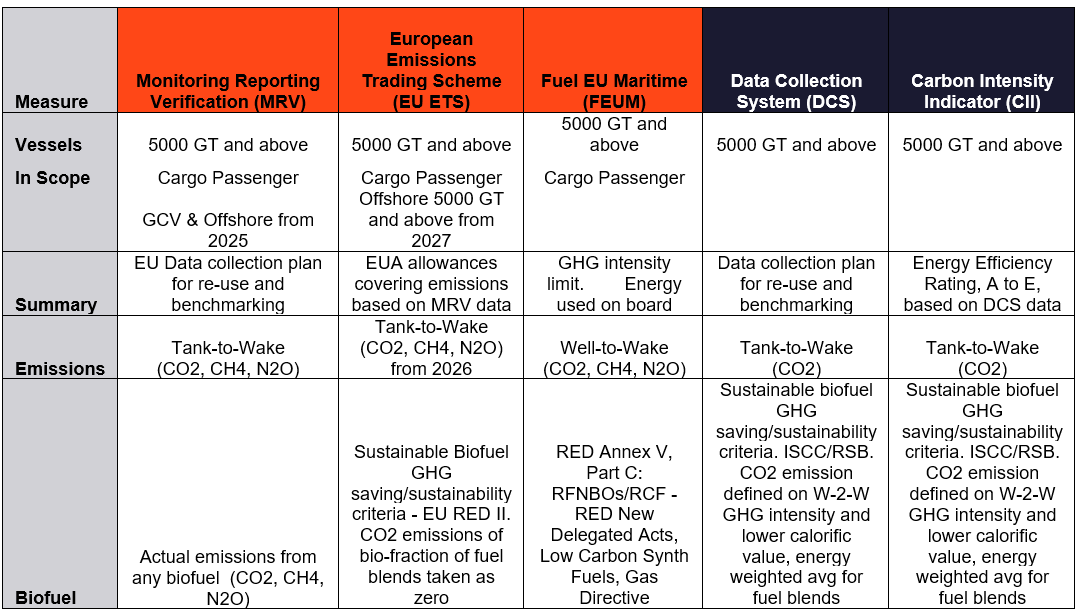

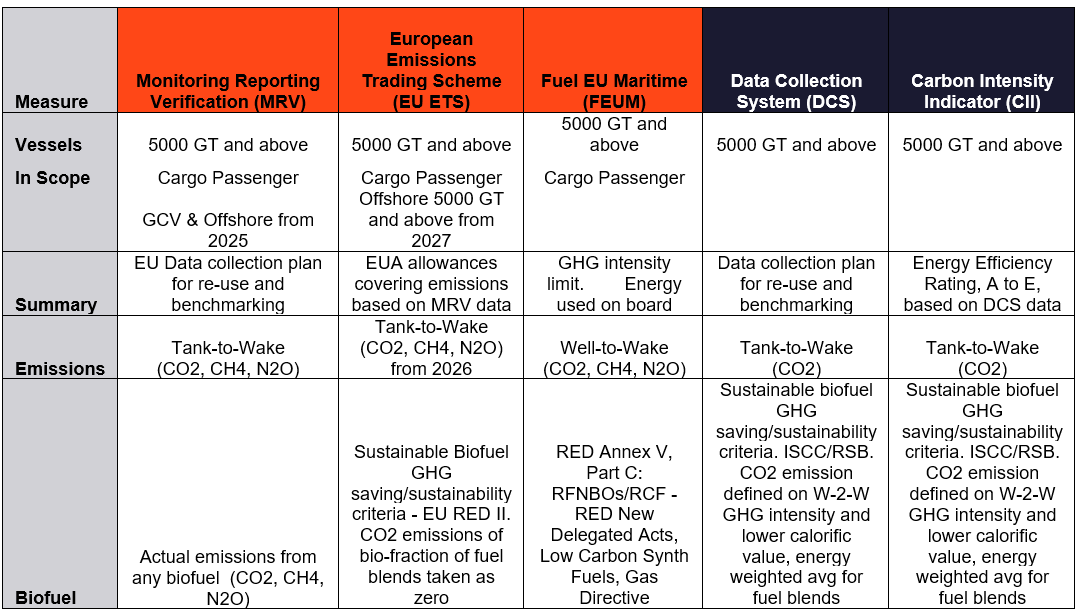

For the period 2024 – 2026, the EU ETS is a tank-to-wake based regulation which covers 100% of emissions from intra-European routes and 50% of emissions from extra-European routes to and from EU calls in neighbouring non-EU countries. Over the same period emissions from maritime transportation carried out by ships of 5,000 gross tons and above will be included, but from 2027 this will be lowered to 400 gross tons and above.

The EU ETS will be extended to cover methane (CH₄) and nitrous oxides (N₂O), not only CO₂, however until 2026, CO2 is the only greenhouse gas to which the obligations apply.

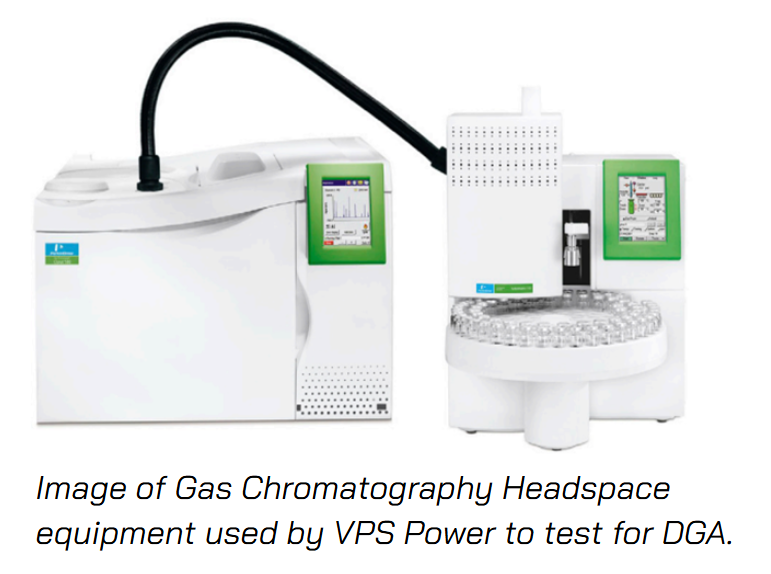

To provide accurate real-time emissions monitoring, the VPS Emsys system can provide measurement of: NOx (NO + NO2), CO2, SO2, CO, CH4, H20, NH3 & O2, via its unique and innovative cascade laser detection system, with ship-to-shore transfer of data through onboard IAS systems or direct network connection, also known as Emsys ShorLink.

Accurate emissions data is critical under the regulations CII, EU ETS, and FuelEU Maritime. With the VPS Emsys system, the streamlining of a vessel’s reporting processes and minimizing risk of costly errors can easily be achieved. Vessels will gain full transparency into their emissions profile. So, no guesswork required and actionable insights for operational adjustments achieved.

The EU ETS implementation is occurring in phases. Shipping companies will be required to surrender allowances for their verified annual emissions as follows:

2024: 40%. 2025: 70%. 2026: 100%

Applying EU ETS:

For Intra EU voyages EU ETS covers 100% of all emissions

For In/Out EU voyages EU ETS covers 50% of all emissions

Associated Fuel Carbon Factors:

HSFO 3.114 gCO2/g, VLSFO 3.151 gCO2/g, MGO 3.206 gCO2/g

e.g For a ship consuming 500mt VLSFO on an Intra EU voyage in 2025 (70% emissions) it would require:

1,102.85 EUAs at a price of €73/EUA = €80,508

If the same ship consumed 500mt of B30 (FAME/VLSFO) it would require:

772.1 EUA at a price of €73/EUA = €56,363

The overall environmental benefit of using the B30 fuel and the impact on the EU ETS cost saving of €24,145 is positive. But the price difference of between the VLSFO and the B30 may be significant, plus the lower energy content of the B30 will also be considered factors.

The laboratory measurement of the energy content of fossil, biofuels and RFNBO fuels will assist in EU ETS requirements. Along with the accurate measurement of the renewable content of biofuels. Here VPS have significantly improved the accuracy and precision of the test method, EN14078, to assist in assurances a vessel will only pay the correct level of carbon taxation.

Fuel EU Maritime which became effective on 1st January 2025, is an EU initiative aimed at promoting the adoption of sustainable fuels and alternative energy sources, with a progressively tightening cap on the greenhouse gas intensity of fuels used, hence reducing greenhouse gas (GHG) emissions from ships operating within EU ports and waters. It sets limits on the GHG intensity of energy used by ships, of >5,000 GT transporting cargo, or passengers, for commercial purposes in the EU/EEA. The requirements start with a 2% reduction in GHG intensity from 2025 to 2029, relative to the average GHG intensity in 2020. This reduction target then increases to 6% from 2030 to 2034 and further accelerates from 2035 to ultimately achieve an 80% reduction by 2050. Shipowners are presented with several flexibility mechanisms to achieve compliance, including banking, borrowing, and pooling, and penalty payments.

To help comply with Fuel EU Maritime, vessel operators have a few options:

Borrowing - Compliance deficits can borrow from the next reporting period, but this is not applicable for more than two consecutive periods. There is a 10% surcharge added to the borrowed amount and its not applicable if the amount exceeds 2% of GHG intensity limit.

Banking – A compliance surplus can be credited to the balance of the next period, but this isn’t available after the FuelEU document of compliance has been issued.

Pooling – This allows ships to merge their compliance balances of GHG and RFNBO to meet requirements. There is a separate pool for GHG and Renewable Fuel of Non-Biological Origin (RFNBO).

Consequences of Non-Compliance – TheFuelEU penalty amounts to EUR 2,400 per ton of fossil fuel exceeding the current limit

If a vessel has a deficit for two consecutive reporting periods or more, the penalty factor grows by 10%.

If a vessel fails to hold a valid FuelEU Document of Compliance for two or more consecutive periods, the vessel may be subject to an expulsion order with a refusal of entry by coastal Member States ports and also the vessel may be subject to flag detention and not allowed to leave flag Member States ports.

Through VPS PortStats platform, users will be able to gain a holistic view on their fuel procurement programmes, by combining price, quality, calorific value and CO2 footprint/costs

The above EU strategies are further supported by the Alternative Fuels Infrastructure Regulation (AFIR) which requires EU ports to develop shore power, plus the introduction of a bunkering infrastructure for low-to-zero fuels.

Staying compliant isn’t just about meeting a set of numbers; it involves ongoing monitoring, reporting, and strategic planning to ensure vessels remain efficient. Traditional approaches to compliance have grown more complex and data-intensive, requiring reliable measurements of fuel quality, emissions tracking, and transparent documentation to satisfy authorities and demonstrate operational excellence.

As part of EU “Fit for 55”, the Renewable Energy Directive (RED) does look towards low-to-zero carbon fuels usage and regarding biofuels it is key that fuel suppliers have their products certified by the likes of the International Sustainability and Carbon Certification (ISCC).

To monitor compliance performance, vessels are required to measure the following and within a specific timeline.:

All the above legislation, highlights the increasing complexity ship owners and operators are now facing in order to ensure compliance. Over the past five years VPS has improved its testing capabilities to incorporate developments in regard to fossil fuels, but more so for biofuels and RFNBO.

In addition, VPS data platforms have been developed from our world-leading databases on fuel and lubricating oil quality. Software solutions, such as BOSS for deep-sea vessel optimisation and Maress for offshore operations, offer a proactive approach to regulatory readiness. By monitoring key metrics (e.g., engine load, RPM, speed, fuel consumption) in real time, vessels can take swift action before small issues become huge compliance headaches. Over time, these tools help benchmark and continuously refine performance across an operators fleet.

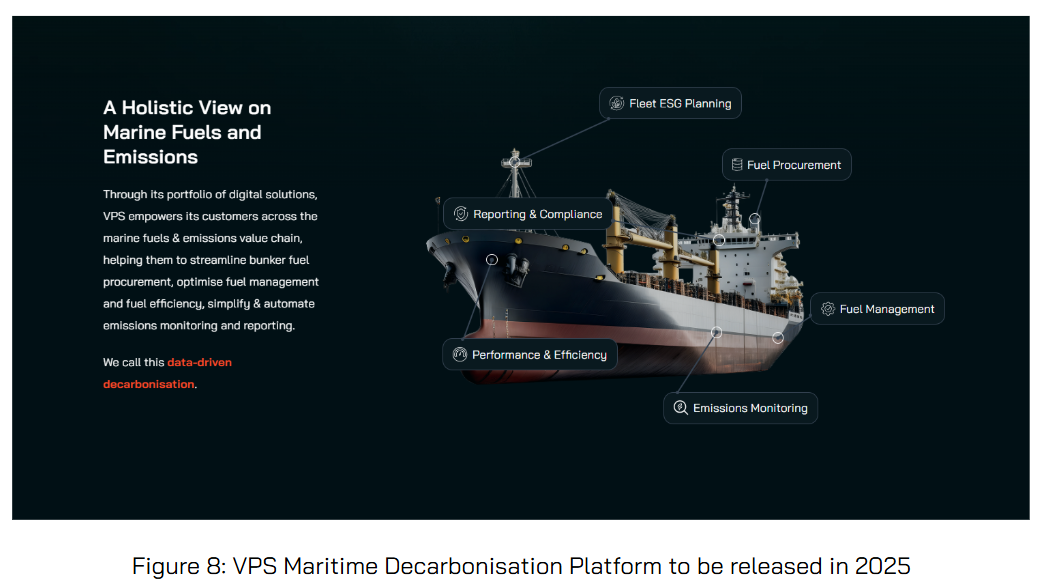

To conclude, VPS offers end-to-end strategic support for maritime decarbonisation. This includes:

- Evaluating Alternative Fuels: Determining which biofuel blend or low-carbon option is best suited to vessels’ routes and operating conditions.

- Compliance Roadmaps: Mapping out steps to meet EEXI, CII, and EU ETS milestones—minimising operational disruptions while keeping vessels on track.

- Crew Training & Engagement: Equipping sea-going staff with the knowledge to achieve both environmental compliance and operational efficiency.

- Fleet Efficiency Assessments: Uncovering opportunities for improvement across an operators vessels to enhance performance and reduce a fleet’s carbon footprint.

- Advanced Technologies & Hybrid Propulsion: Providing guidance on effectively integrating and operating hybrid systems—such as batteries—in different operational modes, so as to maximise efficiency and reduce emissions.

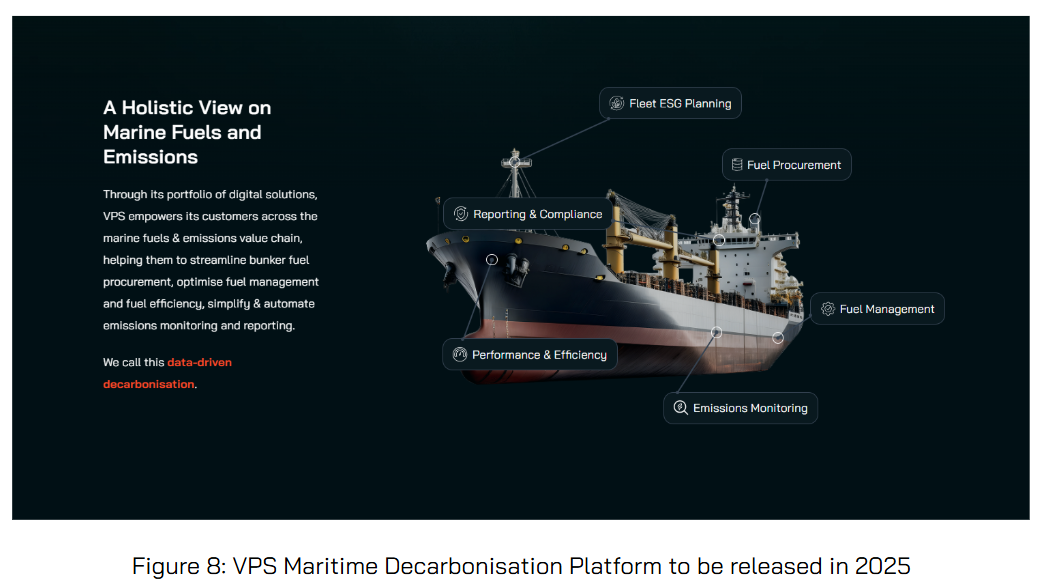

It's important to note that all VPS services are coming together in our new on-line, integrated decarbonisation platform, to be released this year.

As the push for maritime decarbonisation continues—alongside tightening carbon-reduction targets and broader interest in alternative fuels—VPS’s adaptable testing and digital solutions, advanced measurement capabilities, and expert guidance are becoming ever more essential. For operators seeking a competitive edge in an increasingly regulated environment, partnering with VPS goes beyond achieving compliance—it paves the way for long-term resilience and sustainability.

To discuss VPS being your maritime decarbonisation partner, please contact: marketing@vpsveritas.com

Search

Search

Customer

Customer