Article by Wolf Rehder, VPS Area Manager Germany

Prevent emergency equipment from failing during an emergency

The lifeboats, emergency generators, and emergency fire pumps onboard are among the vital critical equipment essential for efficient, dependable, and prompt operation during onboard emergencies and across diverse climatic conditions.

Most companies and vessels have procedures in place to monitor their fuel quality. Close attention is paid to the management of fuels to be used in main and auxiliary engines, regardless of fuel-grade, as this has a direct impact on safety, health and the environment as well as on the economic operation of the vessel.

Most companies and vessels also have routines in place to regularly test emergency equipment. Nonetheless, it seems that in numerous instances, there is insufficient focus on the quality of fuel utilised in emergency equipment.

Fuel grade DMX within the ISO8217 specification is specifically intended for use within emergency equipment. However, since this is not a mandatory requirement, marine gas oil (MGO grade DMA) used for other purposes on board, is often used to fill up emergency equipment tanks. This could lead to hazardous outcomes as the DMA grade fuel might not be suitable for its intended use. The quality of the fuel in the emergency equipment tanks may also deteriorate during storage. Hence it is essential to test and ensure that the quality of the fuel being taken into the tanks is ’fit for purpose’ and monitored at regular intervals.

Impact of various parameters on the operation of the emergency equipment

Cold Flow Properties (Cloud Point and Pour Point)

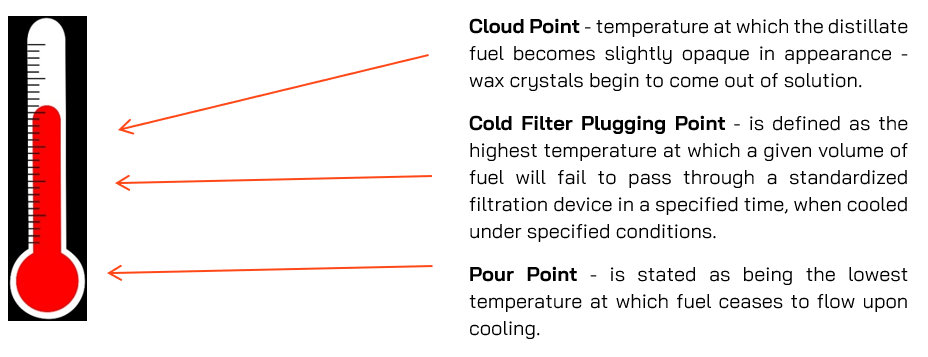

Distillate fuels are predominantly paraffinic in nature and under colder temperature conditions, the paraffins can precipitate from the fuel in the form of wax. As a consequence, this wax can lead to blocked pipework and filters, leading to numerous operational issues including potentially starving the vessel engine of fuel.

Cloud Point (CP) of a distillate fuel is the temperature at which the paraffinic wax begins to separate from petroleum oil and form a cloudy appearance. This is the first indicator of cold-flow issues with a fuel.

Pour Point is the lowest temperature at which the fuel will flow, i.e., the fuel becomes solid.

Whilst the Pour Point of a distillate can be lowered using additives, the Cloud Point is not affected by such additives. This means that even when a distillate has a very low Pour Point, it’s Cloud Point could be very much higher. As the fuel temperature drops to, or below the Cloud Point, wax crystals will start to form, at which point, filter clogging could begin to take place, resulting in fuel starvation and engine stoppage. Satisfactory storage, transfer and filtration needs a fuel temperature about 3-5°C above the Cloud Point. The Cloud Point of fuels used for emergency equipment should be below the ambient temperatures at which the equipment it is operating, or likely to operate.

One real case example saw a fuel in a lifeboat engine storage tank which had a Pour Point of -33°C whilst the Cloud Point was +17°C. This fuel could only be safely used at ambient temperatures above 20°C.

The additives used can also potentially cause operational problems as some of their chemicals can be absorbed by filter materials, causing them to appear blocked. This problem is exacerbated for emergency equipment which are typically fitted with very fine filters.

Fatty Acid Methyl Esters (FAME)

Due to the practice of blending FAME into automotive diesel and heating oil, it is now more common and indeed inevitable, that some distillates supplied in the marine market contain FAME. FAME can lead to complications with respect to storage and handling in a marine environment, due to its increased level of oxidation tendency, long-term storage issues or shorter shelf life, it’s affinity to water and risk of microbial growth. Additional issues regarding FAME’s degraded low-temperature flow properties and FAME material deposition on exposed surfaces, including filter elements, also add to the fuel management concerns. Therefore, testing for the presence and levels of FAME within marine distillates, is a highly recommended practice.

Visual Appearance

Fuels grades DMA/DMZ/DMX should be bright and clear. If the fuel is hazy, it could indicate the presence of water or a high Cloud Point. Haziness could also indicate poor oxidation stability.

Sulphur Content

Vessels (including emergency equipment) required for securing the safety of a ship, or saving life at sea are exempted from the MARPOL Annex VI Regulation 3.1.1 Sulphur requirement. However, for the testing of emergency equipment in an Emissions Control Area (ECA), compliant fuel with sulphur content less than 0.10 % m/m should be used.

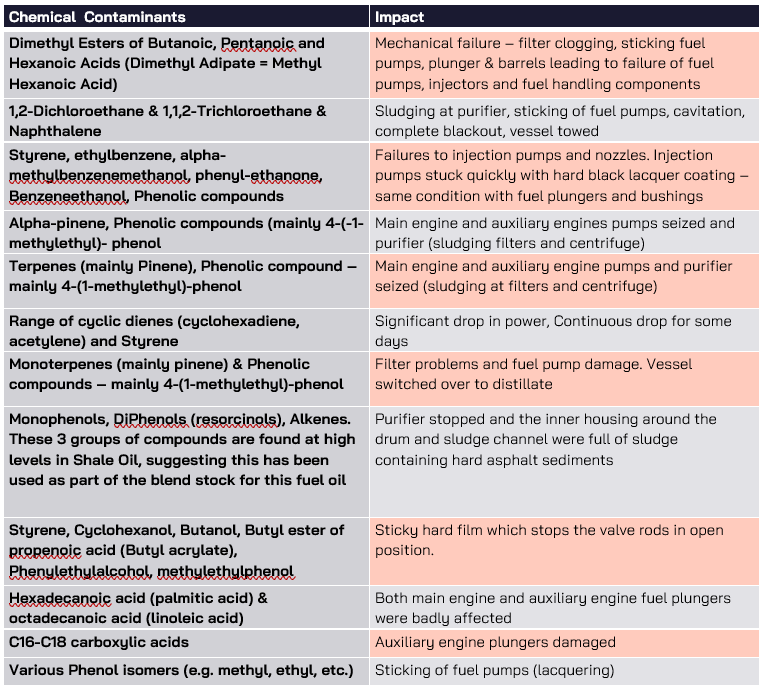

Fuel contamination, a potential hazard

Since fuels in the emergency equipment storage tanks remain unused for long periods of time, quality of such fuels may deteriorate due to the following:

Water can originate from contaminated fuel or condensation, and engines may not run because of water in the fuel lines. The presence of water can promote growth of microorganisms such as bacteria, yeast and fungi, and can also lead to blockage of fuel lines and filters due to icing when ambient temperature drops below 0°C.

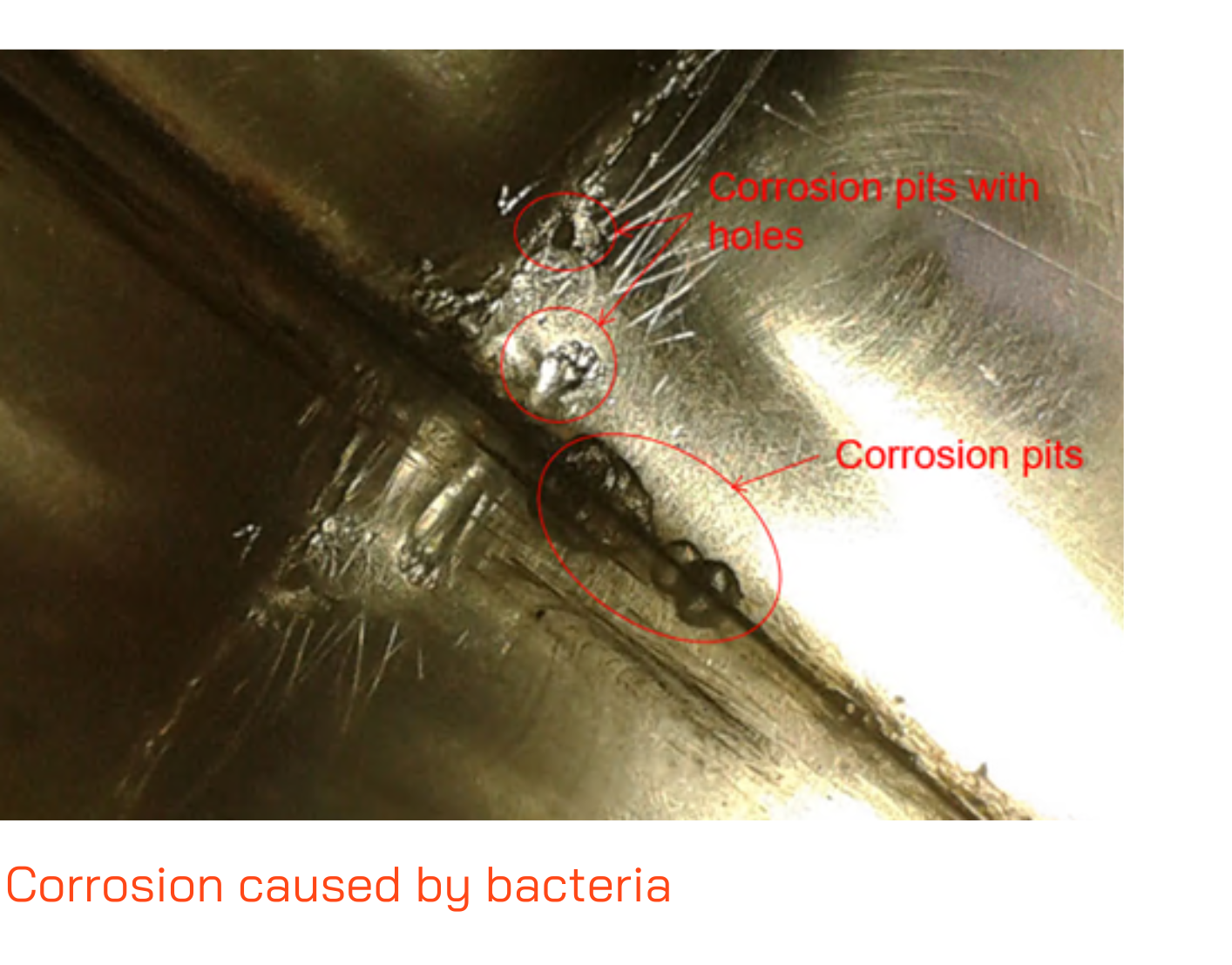

Microorganisms (bacteria, yeast, fungi) – Given the correct conditions in fuel storage systems, micro-organisms can grow and multiply. Bacteria, fungi and yeast are living organisms which may be present in fuel storage tanks and in particular where water is allowed to build up. Distillate fuels are more prone to bacterial infection. Microbial infection can lead to slimy deposits in tank bottoms, plugging of filters, pitting corrosion on fuel tank bottoms or at oil water interface and injector fouling.

Gas Oil Stability – Many different chemical reactions can cause a gas oil to be unstable. Instability can lead to sedimentation and eventually to the formation of gums. Instability is usually indicated by a colour change over a period of time.

Mitigate your emergency equipment risks

It is thus obvious from the above reasons that engines, which should be the most reliable of all, may fail to operate when they are most needed.

Testing of the fuel’s cold-flow parameters, FAME content, sulphur levels, water content and microbiological activity, is highly recommended. These tests will provide vital information and knowledge of a fuel’s quality and the management requirements that go beyond adherence to imperfect specifications. These are necessary to help ship operators deal with fuels which may meet the specification numbers but give serious operational problems.

To find out more about the VPS testing packages for Emergency Equipment, please contact: marketing@vpsveritas.com

Search

Search

Customer

Customer

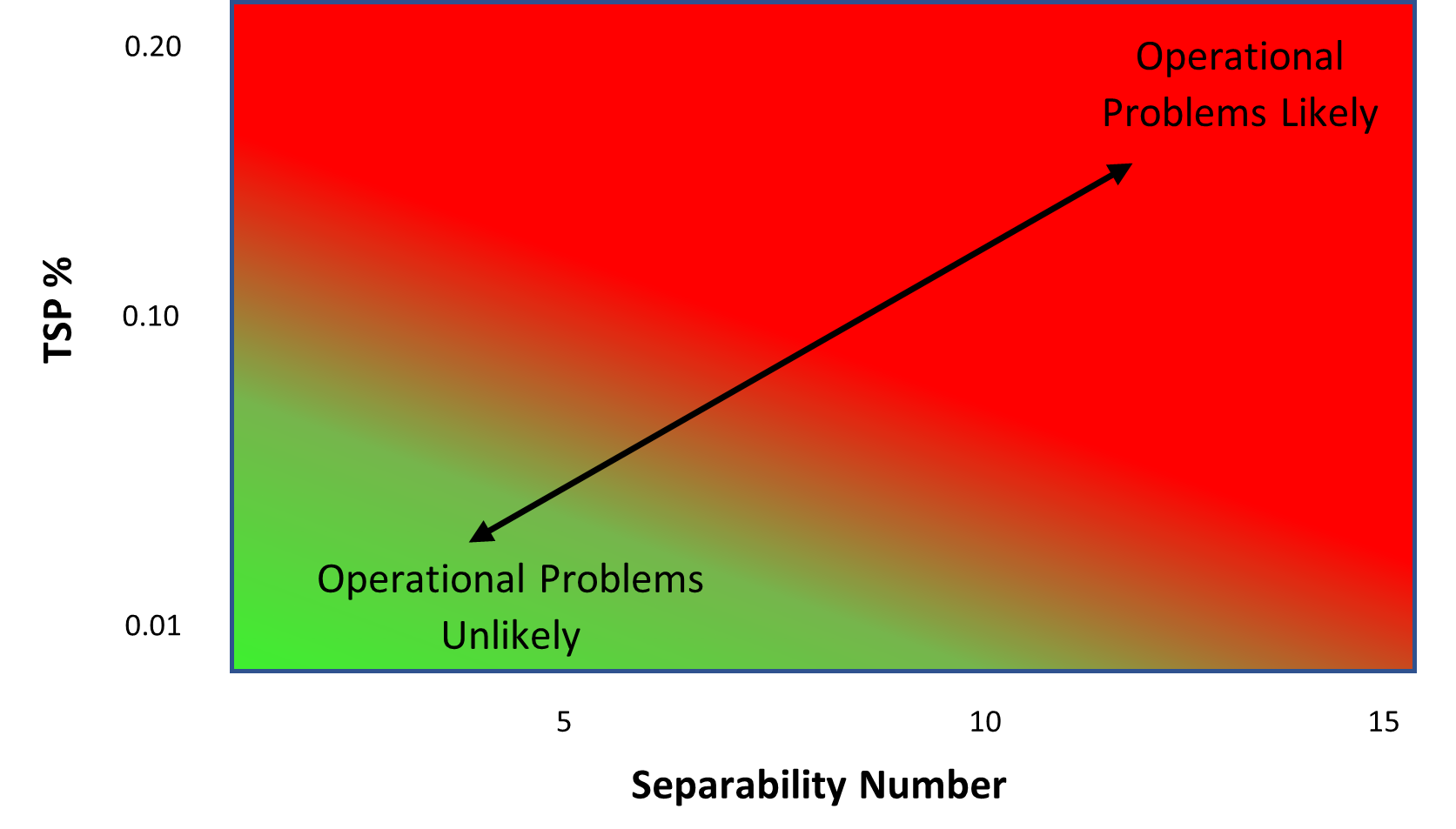

Asphaltenes within residual-based fuels can precipitate as sediment/sludge whenever a fuel’s available solvency to retain asphaltenes in suspension drops below the fuel’s stability reserve. The ISO 8217:2012/17 standard has a sediment limit of a maximum 0.10% m/m to protect buyers’ interest where an elevated sediment value can be indicative of an unstable fuel. Today’s fuels are no longer produced from straight run refining processes, but undergo a series of complex processes, for example, vacuum distillation, vis-breaking, catalytic cracking, in order to extract the lighter end components as much as possible, leaving the bottom end components with reduced reserve stability. The solvency can further diminish with unregulated blending in order to meet the Sulphur compliance levels within MARPOL Annex VI & statutory regulations.

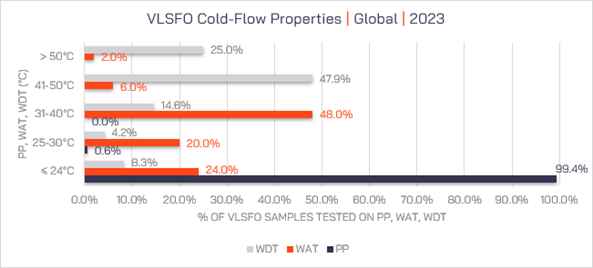

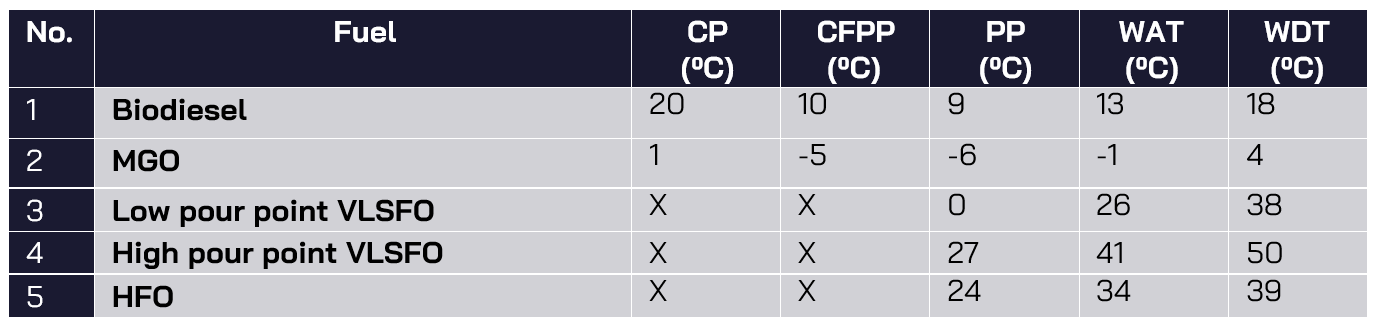

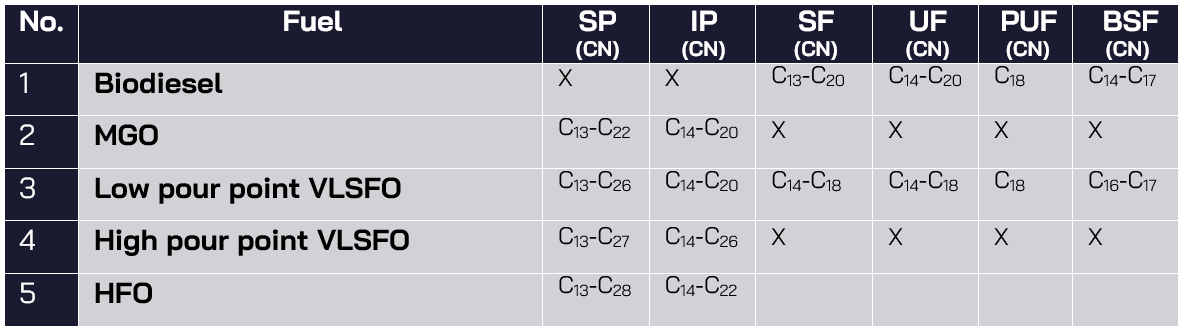

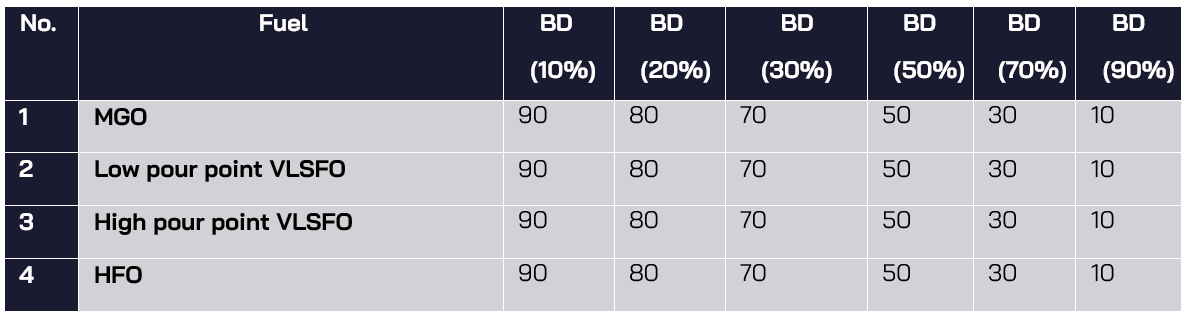

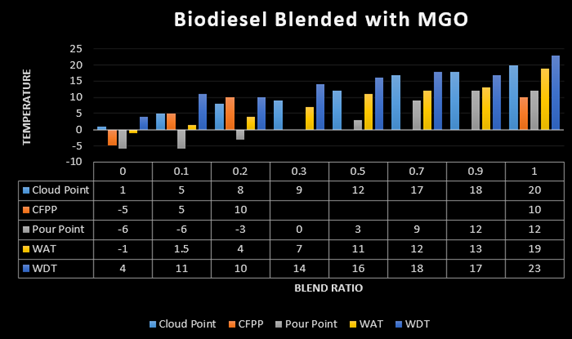

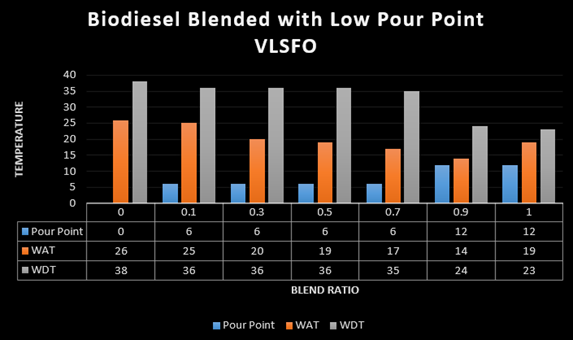

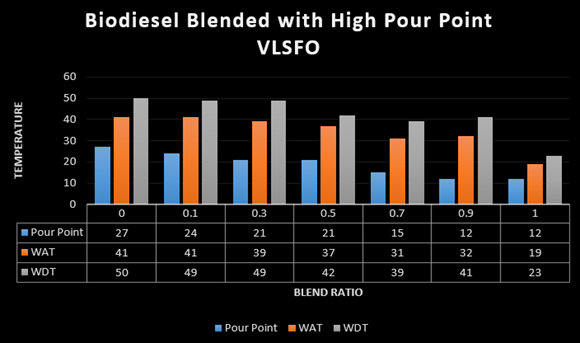

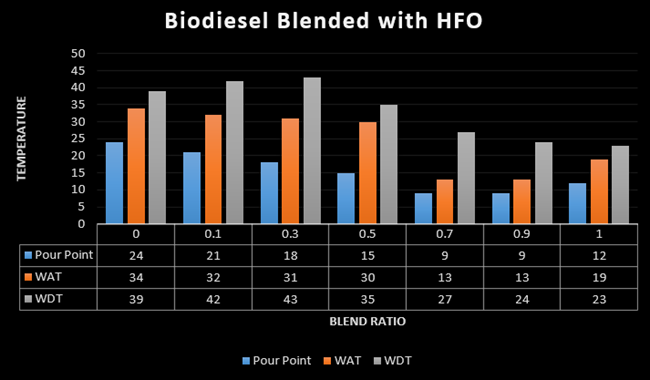

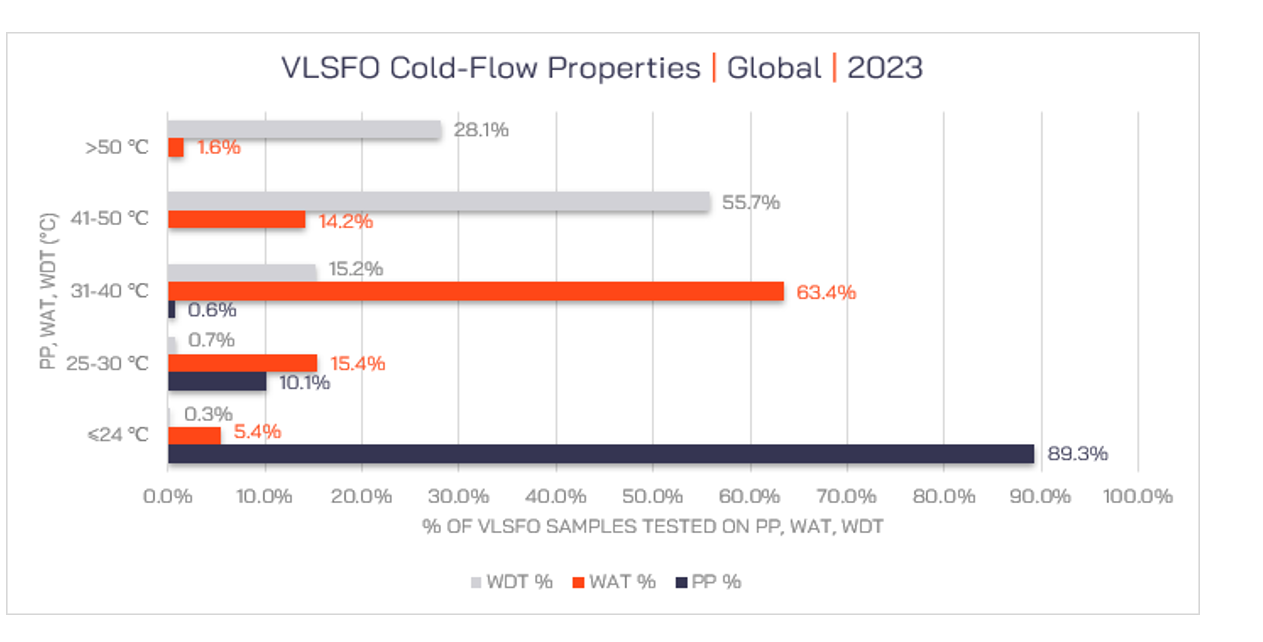

Asphaltenes within residual-based fuels can precipitate as sediment/sludge whenever a fuel’s available solvency to retain asphaltenes in suspension drops below the fuel’s stability reserve. The ISO 8217:2012/17 standard has a sediment limit of a maximum 0.10% m/m to protect buyers’ interest where an elevated sediment value can be indicative of an unstable fuel. Today’s fuels are no longer produced from straight run refining processes, but undergo a series of complex processes, for example, vacuum distillation, vis-breaking, catalytic cracking, in order to extract the lighter end components as much as possible, leaving the bottom end components with reduced reserve stability. The solvency can further diminish with unregulated blending in order to meet the Sulphur compliance levels within MARPOL Annex VI & statutory regulations. VPS 2023 data shows, at least 15.8% of VLSFO samples had a wax apperance temp (WAT) above 40C, including 1.6% above 50C. These samples will precipitate wax if storage temps are not kept above the WAT, compared to the lower storage temperature requirements based on their tested pour points. Wax formation is a reversible process, so theoritically, it should not cause any operational issue as long as fuel remains stable, but unfortunately, fuel stability is not guanteed. Moreover, if wax is allowed to form, wax and aspheltenes (sludge) can co-mingle together as a result, the wax disappearnce temperature may increase significantly and in the worst case, the wax may no longer disappear. Taking a middle approach and strking a balance could be one option where the fuel is not severly overheated, nor the wax allowed to form freely during storage and only increase temperatures during transfer if needed. VLSFO with such high WAT/WDT will need close attention and care during storage, transfer, treatment and use. Prolonged storage should also be avoided for such fuels.

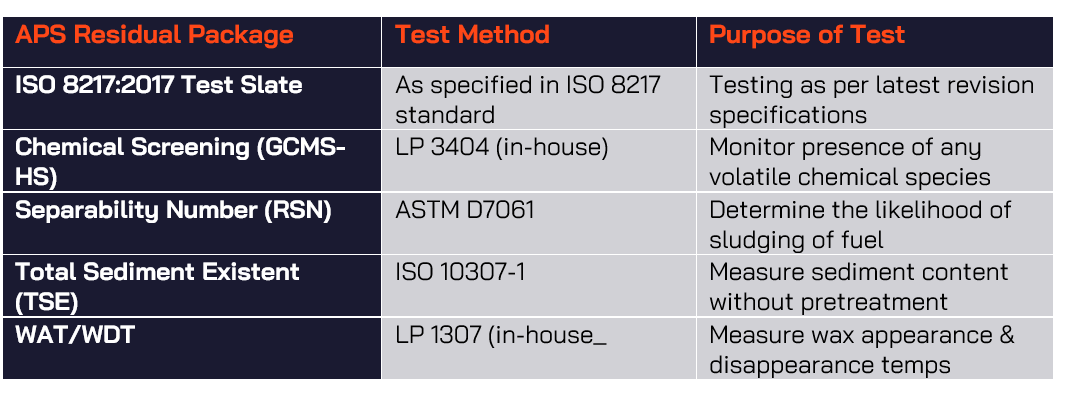

VPS 2023 data shows, at least 15.8% of VLSFO samples had a wax apperance temp (WAT) above 40C, including 1.6% above 50C. These samples will precipitate wax if storage temps are not kept above the WAT, compared to the lower storage temperature requirements based on their tested pour points. Wax formation is a reversible process, so theoritically, it should not cause any operational issue as long as fuel remains stable, but unfortunately, fuel stability is not guanteed. Moreover, if wax is allowed to form, wax and aspheltenes (sludge) can co-mingle together as a result, the wax disappearnce temperature may increase significantly and in the worst case, the wax may no longer disappear. Taking a middle approach and strking a balance could be one option where the fuel is not severly overheated, nor the wax allowed to form freely during storage and only increase temperatures during transfer if needed. VLSFO with such high WAT/WDT will need close attention and care during storage, transfer, treatment and use. Prolonged storage should also be avoided for such fuels.  VPS additional protection service (APS) package

VPS additional protection service (APS) package