By Steve Bee, VPS Group Commercial & Business Development Director

Earlier this year, VPS led the way in detecting and identifying the cause of the fuel contamination issue in Singapore, which raised widespread panic across the shipping industry.

An estimated 200 vessels received HSFO bunker stems containing chlorinated hydrocarbons, which caused damage to approximately 80 vessels. Whilst the Singapore case was one of the world’s largest ever fuel contamination events, the presence of this specific chemical contamination was not a unique occurrence. Almost twenty years ago, trichloroethylene was detected in heavy fuel oil supplied in Fujairah and over the past two decades, chlorinated hydrocarbons have been detected on numerous occasions across the world’s ports by VPS using GCMS.

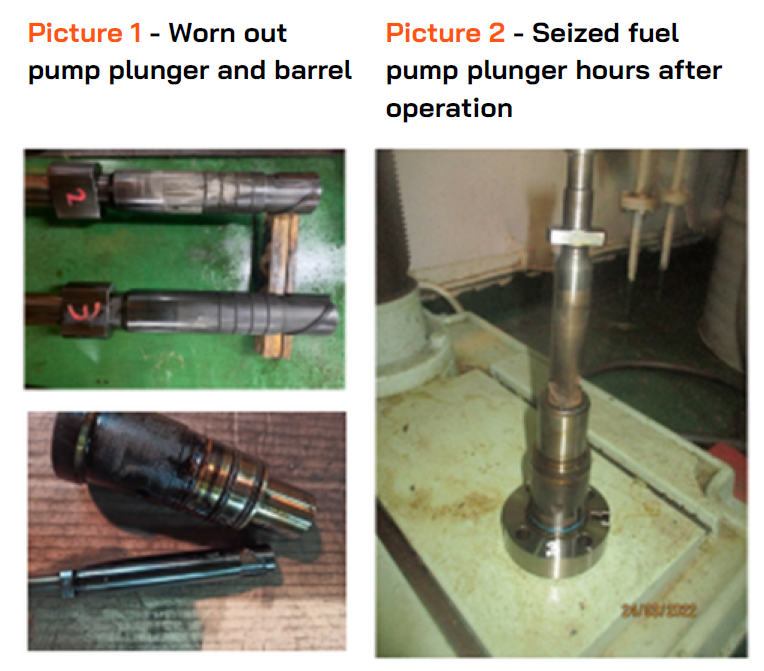

The effects caused by the presence of chlorinated hydrocarbons witnessed onboard vessels range from, complete engine blackout (affecting main engines and auxiliary engines), to fuel pump corrosion, plungers sticking in the barrel, main fuel engine plunger damage, fuel sludging, filter blockages and elevated exhaust temperatures.

Vessel owners and operators are quite rightly concerned over the potential risks chlorinated hydrocarbons pose to their ships. Expensive engine and fuel delivery system damages, plus risks to crew health and safety and potential costly delays and loss of earnings, can all be consequences of such contaminated fuel being stored and used onboard.

But it is not only the vessel owners and operators who can potentially suffer damages and losses due to chemical contamination. Fuel suppliers are also at risk of unknowingly supplying such fuels containing chlorinated hydrocarbons and other potentially damaging chemical groups. Expensive claims, loss of operational licences and catastrophic reputational damage, have all been outcomes suppliers have suffered due to the presence of chemicals in their products.

For many years VPS have provided marketleading GCMS services, which protect our customers from potential damages due to chemical contamination of fuel.

The first step is to use the relatively inexpensive, GCMS-Headspace Chemical Screening, which is a rapid, pre-burn service, which qualitatively detects a range of volatile chemical contaminants. During 2021-22 almost 8% of all VPS screening tests indicated a “caution” result, meaning the test had identified a higher concentration of a potentially damaging chemical compound within the fuel sample.

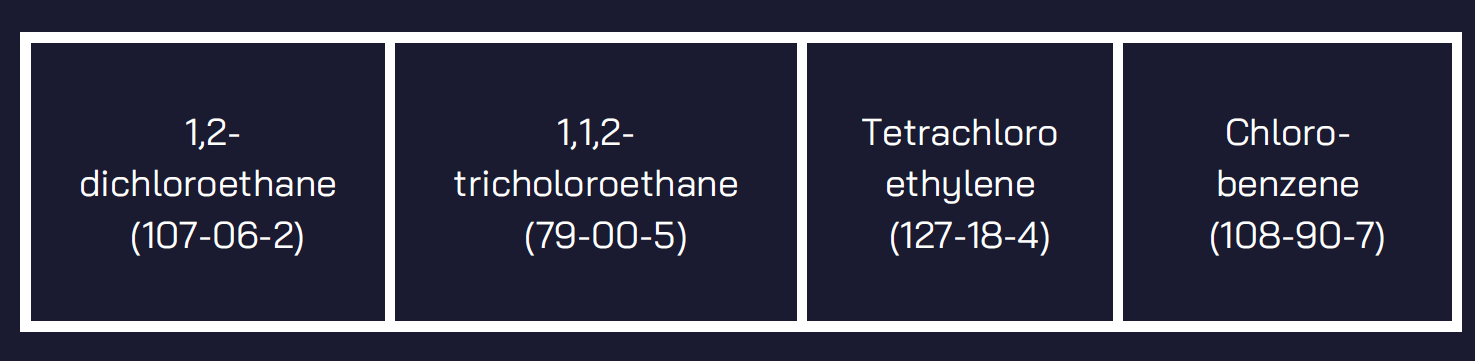

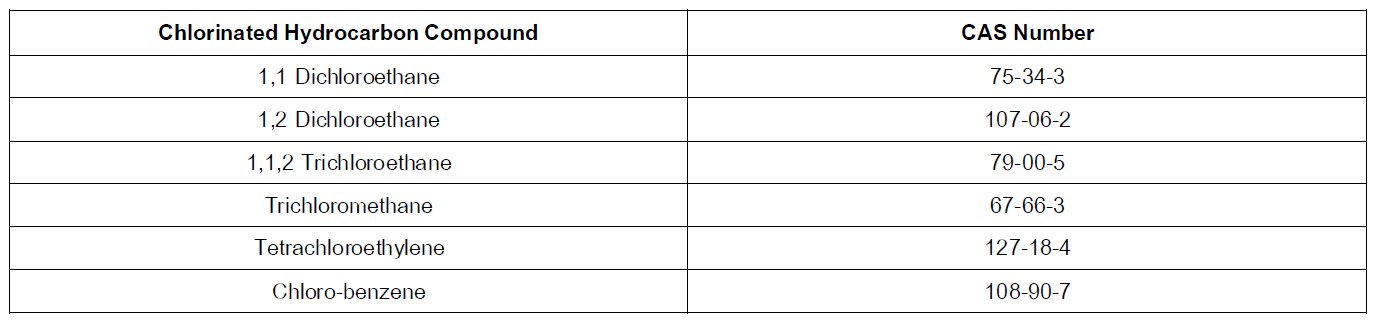

When a “caution” result is seen, VPS conduct an Extended-Headspace GCMS analysis, which provides a more detailed analysis of the sample. Following this if required, analysis can move on to an even further detailed quantitative GCMS-Vacuum Distillation test. Returning to the Singapore case back in March 2022, VPS identified the contaminants as four specific chlorinated hydrocarbons:

• Di-hydro dicyclopentadiene: Chemical CAS Number: 4488-57-7

• Tetra-hydro dicyclopentadiene: Chemical CAS Number: 6004-38-2

These compounds are not part of the refining process of crude oil and as such, should not be present within marine fuels, as stated under Section 5 of the international marine fuel standard, ISO8217.

As a result of these initial findings, the MPA invited VPS to assist in their investigation. VPS were able to provide further evidence of the presence of the contaminants, their source, behaviour, plus how and why such chemicals cause the damages witnessed by the vessels, which suffered when using the fuel. VPS identified 8 supply barges within the port that were contaminated with these chlorinated hydrocarbons. Correlation of VPS results showed that when the concentration of total chlorinated hydrocarbons was less than 100mg/Kg, then no damage was caused to the vessels fuel delivery system or engines.

In Week 43 of 2022, the International Council on Combustion Engines (CIMAC) published its findings on chlorinated organic compounds based on their research into the Singapore case. In their view, more than 100 vessels had suffered operational problems after taking on the contaminated HSFO fuel.

The CIMAC Working Group determined there was and is, a correlation between the elevated levels of chlorinated hydrocarbons within fuel and vessel equipment failure. As a result, the Working Group recommends that marine fuels should keep the level of chlorinated hydrocarbons present, below 50mg/Kg, as a tolerable de minimis level.

CIMAC stated the EN14077 test method could be used to screen for the presence of total organic chlorides. However, the CIMAC Working Group also stated GCMS testing would be required to identify the individual contaminants, detection which the VPS GCMS methodologies provide.

GCMS-HS Chemical Screening can and will provide rapid detection of not only chlorinated hydrocarbons, but also a host of other potential contaminants. This technique can be a frontline defence in protecting vessels from the potential risks such chemicals can pose to the shipping industry and the damage they can inflict upon vessels and vessel operations. VPS has applied GCMS Chemical Screening to more than 100,000 bunker samples since 2016, serving over 400 shipping customers to protect their vessels.

VPS therefore makes the following recommendations:

1. Shipowners who are not already conducting the chemical contamination screening test should review their fuel management strategy to minimise risk.

2. Be clear on how the chemical screening will apply in terms of 1st level, 2nd level or 3rd level evaluation.

3. Once the chemical contamination review has started, build a database to evaluate higher risk ports & cause & effect considerations.

For more information regarding GCMS-HS Chemical Screening and further GCMS methodologies, please contact your local VPS Account Manager for details or mail to: info@vpsveritas.com

Search

Search

Customer

Customer